User Tag List

Results 31 to 45 of 73

-

12-07-2016, 12:27 PM #31

5000 RPM

5000 RPM

- Join Date

- Mar 2009

- Location

- Maine

- Posts

- 135

- Thanks (Given)

- 1

- Thanks (Received)

- 1

- Likes (Given)

- 1

- Likes (Received)

- 7

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

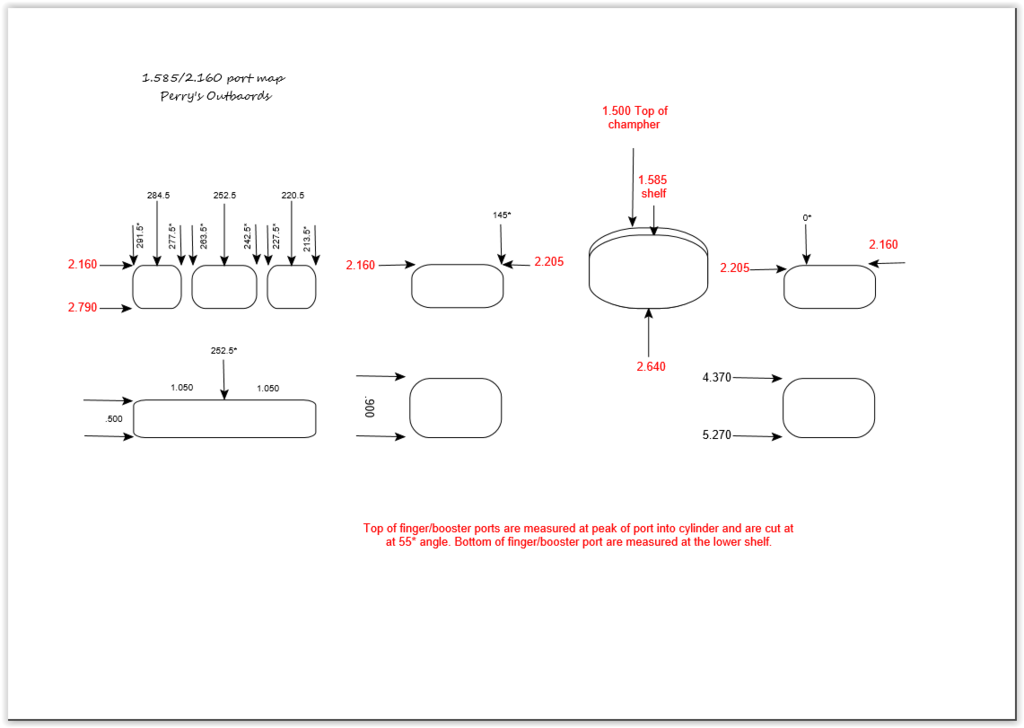

Awesome port map!

James, I am doing up a 97 Mariner Super mag 200 efi. What RPM range is this port map optimized for? Will it work for a 6500 rpm motor? Wondering if I want to raise my exhaust ports this high for a 1500 lb boat? 20 ' Alley Cat.

Beautiful block job, trying to make mine look this pretty, just got my Bridgeport mill

wired and running...

Thanks, Dave Leonard

-

12-07-2016, 02:32 PM #32

I am speachless in this work. Great Job and also, all my condoleances for your loss.

Have a great Holyday period and may all the best for you in the comming yearGlastron GT 150 W OMC 140

Glastron GT150 w OMC 235

Hydrostream Vision with 2.0l 135

Hydrostream HST w 3.0L 225

I know two things that are infinite, the Universe and Human's Stupidity, although I am not sure about the first one.

-

12-07-2016, 10:45 PM #33

Your block has the same porting as a 225 PM. This port map is just a little more aggressive but not by much. The differences between the two is the exhaust exit (bottom of block), rod slots, and 7 petal front and of course ECU. This is a 200 turned to 225 PM. This port map is conservative but will turn 6500 on the right application with no problem. This would increase the power band by a couple of hundred RPMs. Did you get a VFD or rotary converter to hook up your mill? I run VFD on both my mill and lathe and this allows my CNC computer to turn them on and off and 1 of 7 speeds or infinity of speeds with the controller.

James Perry

-

12-07-2016, 10:46 PM #34

Thank you everyone for all the thoughts and prayers. It really means a lot to me.

James Perry

-

RON FIELDING liked this post

RON FIELDING liked this post

-

12-08-2016, 01:05 AM #35

5000 RPM

5000 RPM

- Join Date

- Mar 2009

- Location

- Maine

- Posts

- 135

- Thanks (Given)

- 1

- Thanks (Received)

- 1

- Likes (Given)

- 1

- Likes (Received)

- 7

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Thanks James. I just don't want to turn my 200 into a 150!

I used a 3 hp 3 phase motor, and a static phase converter to start it , to make a rotary converter. Got the motor free, and the static box for $60. Seems to work well, would have used a vfd had I thought about it before i did it, but had the parts for this lying around. Seems to work really well. Guess I should not have sent out the block for machining, but did not have the mill working yet, I'm sure I can find another motor to play with..

Appreciate the help.

Dave Leonard

-

12-08-2016, 07:56 AM #36

Supporting Member

Supporting Member

- Join Date

- Jul 2013

- Location

- California

- Posts

- 1,678

- Thanks (Given)

- 22

- Thanks (Received)

- 82

- Likes (Given)

- 106

- Likes (Received)

- 361

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Just had to post his.

So where is the response from the guy who started the thread? Haven't heard a word from him. Gets excellent work on a replacement block provided by James because his was a pos, six sleeves back to standard, machining and porting matched to a 225 and then some. All for $250.00!!!!! For a block that is better then a new Promax block.

Shameful for no response on this thread after being taken care of so well. People never cease to amaze me.

-

-

12-10-2016, 03:20 PM #37

Me and bullet ,the starter of the thread, are good. I actually sold him a 7 petal front and reed plate to finish up this project. When he sent me payment he sent me quite a bit extra as a peace offering that he did not have to do. I will still do work for him if the future if needed as there are no hard feelings.

James Perry

-

Slimm liked this post

Slimm liked this post

-

12-10-2016, 03:23 PM #38

If you ever got the notion to go CNC let me know. I would be happy to help. Not as hard as one might think. I CNC'd my bridgeport for $1,250.00 and could not tell you how much I love being able to do the things I can do now. I am going to continue to upgrade my set up like making new motor plates now that I can do a better job on them.

James Perry

-

Slimm liked this post

Slimm liked this post

-

12-10-2016, 10:29 PM #39

5000 RPM

5000 RPM

- Join Date

- Mar 2009

- Location

- Maine

- Posts

- 135

- Thanks (Given)

- 1

- Thanks (Received)

- 1

- Likes (Given)

- 1

- Likes (Received)

- 7

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Cnc

Thanks James.

Funny story, I sold CNC lathes and mills and Grinders in Maine and NH for about 20 years, I worked as a CNC Machine salesman, applications, turnkey projects, all kinds of job shop and manufacturing accounts.

But I always wanted my own machine, never got around to it. At the end of doing that, I did a deal with a customer shuffling a few used machines around, and I ended up with this Bridgeport clone. A Victor with 54" table, 18" y, Mitutoyo readouts, etc.

Had it collecting dust and wife and kids kept trying to get me to clean it out of the garage, but I just couldn't part with it. Had the phase converter, and just never got around to buying tooling and wiring it up.

So having fun playing, buying tooling etc. Takes, as you know, vises, collet sets, clamp kits, End mills, machinists inspection tools, boring heads, etc.

But I'll probably skip the cnc, I am curious how you did it so cheaply, did you convert to ball screws and use a pc based control? If you want to buy a small good toolroom cnc mill I think the Trac Mills are pretty resonably priced and good in toolroom applications.

The Haas stuff is pretty cheap these days, if you want a bed mill.

-

Slimm liked this post

Slimm liked this post

-

12-11-2016, 03:13 AM #40

Time to upgrade my Smithy 3 in 1. I'm feeling underpowered.

If I don't ask any questions, I'll never learn anything.

-

12-11-2016, 09:35 PM #41

Still using lead screws with an adjustable nut for now. I am using Mach3 PC based program that will compensate for the backlash. I am going to install x,y ball screws and bearings which will be about $1,100 for them. I already have the ball screw for the Z. I am still running off the shaft and gear on the Z. I moved it to the left side as I am always tilting it for the 2nd stage on sleeves and need the z to be power. I am using 4 stepper motors (4 axis X,Y,Z, and A) at a 2:1 ratio and have it on 40 IPM max (have ran it a 100 IPM) and due to the spindle speed of 5450 I run about 12 IPM when cutting sleeves. I am very satisfied with the set up for what all it can do.

James Perry

-

12-11-2016, 09:58 PM #42

5000 RPM

5000 RPM

- Join Date

- Mar 2009

- Location

- Maine

- Posts

- 135

- Thanks (Given)

- 1

- Thanks (Received)

- 1

- Likes (Given)

- 1

- Likes (Received)

- 7

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

James,you

are truly impressive. Sounds like quite a project. Lot harder than building a motor. I have worked on a bunch of cnc machines, but sounds like you are building them. You could probably pick up a fully cnc used knee mill for $5k, might be worth it to you at some point.

Dave

-

12-12-2016, 07:43 AM #43

I have never met Mr. Perry however he has gone out of his way to help me get one of my mills set up like his. I called him once and he has called me several times to see how I have progressed. Hell of an intelligent, talented man looking out for someone he has never met. We could sure use more guys like this.

RockTeam Junk

No sparkling wiggles in here, only dump truck grinches.

"Screamin Heathen"

-

frank jackson thanked for this post

frank jackson thanked for this post

-

12-12-2016, 11:23 PM #44

Thanks guys dor the confidence boost.

James Perry

-

12-13-2016, 11:56 PM #45

"Whacker Smacker" #561 IHBA M/E div1 2007& 2006 first looser champion

"Whacker Smacker" #561 IHBA M/E div1 2007& 2006 first looser champion

2007 Sportsmen Driver of the Year

Similar Threads

-

who to send a block to ?

By evinrudejohnson in forum Technical DiscussionReplies: 137Last Post: 08-22-2017, 07:06 AM -

best place to send a block for a sleeve install ?

By WATERWINGS in forum Technical DiscussionReplies: 21Last Post: 04-20-2012, 07:23 PM -

Where To Send 280 Block

By myron in forum Technical DiscussionReplies: 11Last Post: 07-05-2006, 11:32 PM -

Where to send block for Nicasil sleeve

By iwannagofast in forum Technical DiscussionReplies: 2Last Post: 05-13-2004, 12:57 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote