User Tag List

Thanks: 0

Thanks: 0

Results 1 to 15 of 26

Thread: Nik sleeve puller

-

12-18-2016, 12:42 AM #1

Nik sleeve puller

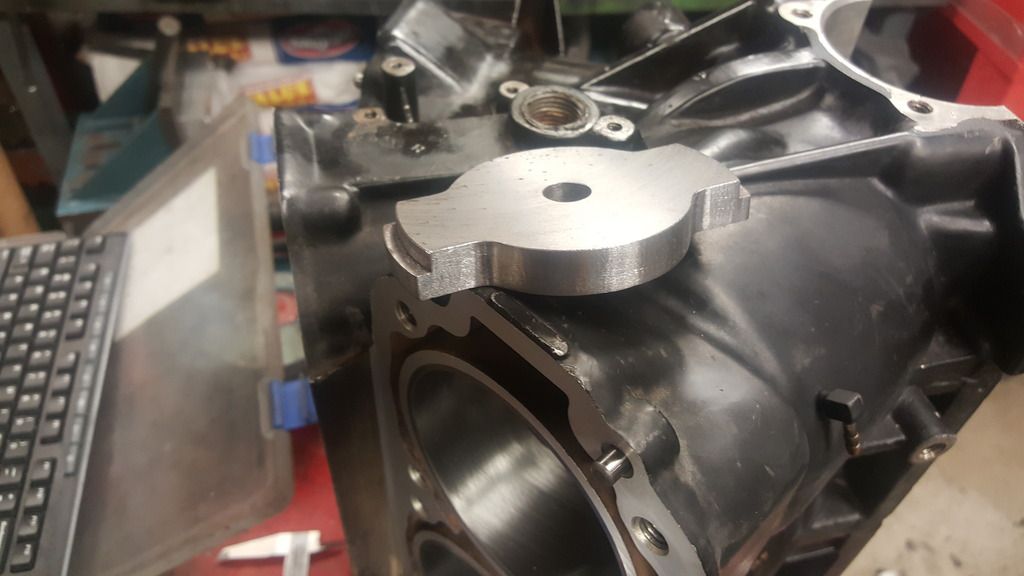

I said earlier today I would post if a sleeve puller I had made worked and it did. I pulled two sleeves out of a 260 and only lightly scuffed the sleeve at the bottoms and are still very usable. Now I can reverse engineer the sleeves and start cutting them out of aluminum to have them plated. Going to try a different approach later and see if it helps on set up hassles. My first attempt the adapter folded into a V shape when the sleeve got about halfway out, good thing it was a bad sleeve! The tool was redesigned and made to be a lot stronger. It has a step on it to center itself in the ports so the tool does not get into the block and is held directly in the center of the sleeve.

First attempt.......

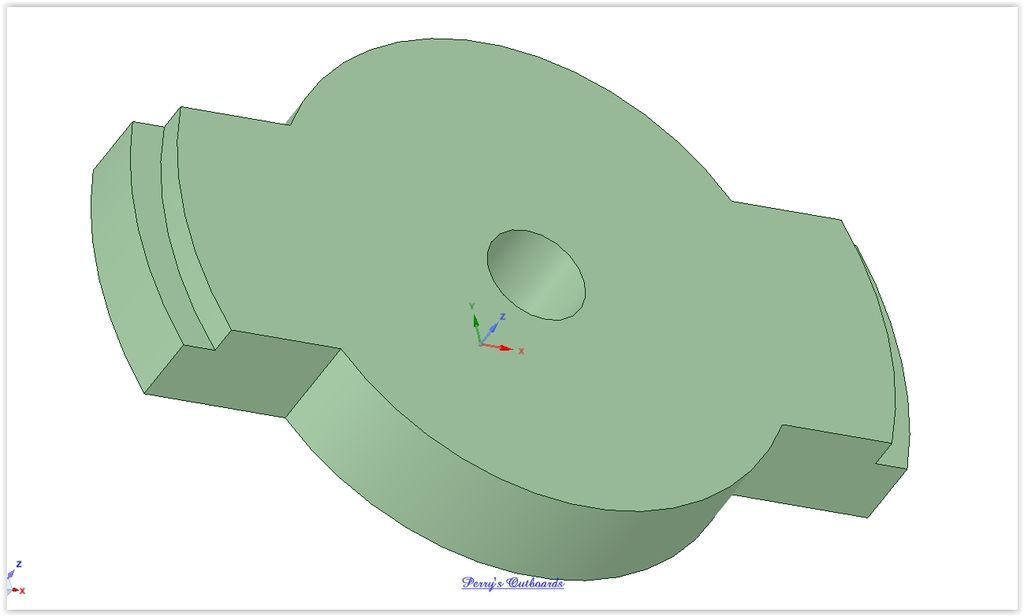

New design adapter drawn up in cad

Adapter cut from 1/2 scrap metal

Puller adapter finished

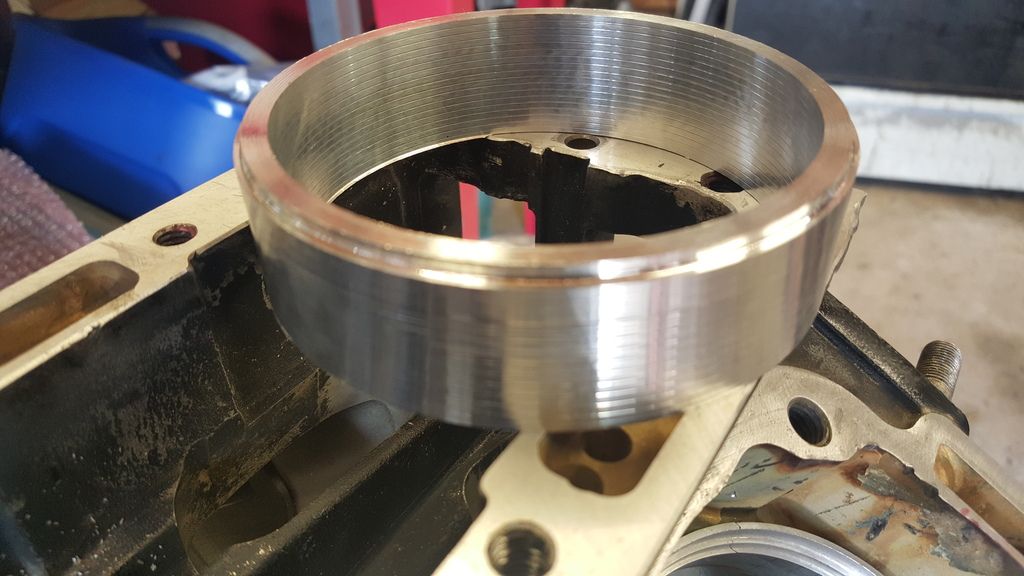

Receiver for the sleeve

Puller assembly on block

SUCCESS!!!!

James Perry

James Perry

-

Capt.Insane-o, tux974, Tom Foley, rock, moldman, W2F a V-King, timmc6, powerabout, NICE PAIR liked this post

Capt.Insane-o, tux974, Tom Foley, rock, moldman, W2F a V-King, timmc6, powerabout, NICE PAIR liked this post

-

12-18-2016, 11:02 AM #2

The one my kid built a few years ago ( 3.0L ) has a one tab longer than the other on the extractor plate . You go in a little sideways , long tab first , then the short one . Slide all the way over to the shorty , and pull the sleeve . I quit using the "screw jack" cold method . If (when) it transferred metal and started balling up , it would break the top half of the sleeve off . Hot , he could pull all 6 in less than 10 minutes .

2.5 NIC stuff , I have ( so far ) just bored them thin and used a scribe to just hook and pull . The block's register from the top of the exhaust port to the deck is so delicate , that i have made an outer ring that slips over it to provided stability while doing anything from boring , installing and honing .

Puttin them back in is the fun part ... LOL

Then bringin em up to size is an expensive , bring your lunch , process ...

-

12-18-2016, 05:55 PM #3

Chaz,

I am just pulling them for reuse. The block is toast. It does put some light scratches on them but is below the ports so not critical, I have had to repair the blocks register(as you call it LOL) by boring out to 3.900 and making an aluminum sleeve with larger ports cut in. I have found a way to make them go in a lot easier and I am using .002 interference to make sure they seal then install a sleeve with .003 interference to better the seal. Have done a couple with good success. Here is one I done a while back.

Bore out block and removed top of register.

Made a repair portion. Had to hand blend slightly. Notice the shoulder on it.

I installed the repair sleeve

Then I had to go through and blend the ports to the block, bore it, and installed a new sleeve. Not shown

James Perry

-

-

12-18-2016, 06:34 PM #4

6000 RPM

6000 RPM

- Join Date

- Aug 2011

- Location

- ct

- Posts

- 1,017

- Thanks (Given)

- 0

- Thanks (Received)

- 12

- Likes (Given)

- 2

- Likes (Received)

- 65

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

James you do some awesome work!! The stuff you guys comes up with is great

-

-

12-18-2016, 06:48 PM #5

-

12-19-2016, 09:00 AM #6

I had forgotten we spoke about : easier sleeve installation thru modern chemistry ..

That's a heck of a block repair , without having the same amount or more blown out of the floor / rod slot area ... I assume the shadow on the deck of the center hole had something to do with it . We can save that one for our next phone call ..

I assume the shadow on the deck of the center hole had something to do with it . We can save that one for our next phone call ..

Big diff between guys who say ... it's junk , and those who can come up with a working repair ...

-

-

12-21-2016, 10:14 PM #7

The one above had a severely damaged receiver. The above block was already had a .040 sleeve in it. Replacing the receiver was the only repair for it.

Here is what I normally do for damaged receivers. I go through and cut the top out placing 2 ledges on the receiver. One for the repair sleeve to sit on then the 2nd one creates a gap for me to place the weld into. Yes, that is a crack above the exhaust port.

The repair sleeve has a single lip on it. Sorry blurry pic.

Then I hold it in with bolts and fill in the gap!

James Perry

James Perry

-

-

12-21-2016, 10:48 PM #8

nice work!

-

12-22-2016, 07:54 AM #9

His pictures are really good... But it's way better looking at it in person.

He can repair things that others would condemn to the scrap pile. Which is good, like he told me some of these old blocks and parts are not in production anymore and getting harder to find

Amazing.

James

-

NICE PAIR liked this post

NICE PAIR liked this post

-

12-22-2016, 04:30 PM #10

The top pic of post #3 is how the 2.4 blocks looked when u machined them for the 3.5 in bore kits with the big flanged cast sleeves befor the 2.5 came out.. i built one back in the day it ran really good. You do Really nice work. Dave

-

12-25-2016, 11:50 AM #11James called it the register ...... LOLBore out block and removed top of register.

Man ya had to really chase that one way down the "sleeve holder" ...

Register :

verb ; a: to make or secure

b: to be in correct alignment or register

Tough call sometimes , whether to leave as much of the parent material as possible and fix what's there or get rid of all and start fresh . I would think that if you can get 75% penetration .. all will be well .

As always , your machine work is 100% ...

Here's one I could send ya ifin ya wanna give it a shot ...

-

12-25-2016, 12:00 PM #12

Somebody was a little rough on their briggs and stratton

-

12-25-2016, 08:32 PM #13

Looks like off a Porsche 911 air-cooled engine.

Checkmate 2002 Convincor 270 496 MAG-HO

2003 Cougar 22MTR w/300xs SOLD

90 21Skater w/300xs - sold

98 STV Euroski w/280 - sold

2006 Trailblazer SS 6.0l 395hp

-

12-25-2016, 11:06 PM #14

Briggs + Stratton ... LOL

I might get away with saying that , but when I'm over at the Porsche~n~housin , I never use the words , Volks , Gia or the gestapo ...

They are building a POLO for a 356 . In the article they did a 4 into 1 . I'm going to do a pair of 2 into 1 Y pipes that merge into a muffler that's gonna be two megaphones hidden in a box ... at least that's what it looks like in my nightmares ...

http://www.enginelabs.com/news/polop...-the-flat-six/

-

12-26-2016, 12:36 AM #15

At least it'll be easy to replace the valve seats before you weld it all back together.

Similar Threads

-

2.5 sleeve clearence between piston and cast iron sleeve

By great adventure in forum Technical DiscussionReplies: 1Last Post: 07-05-2010, 07:29 AM -

Carrier Puller???

By P man in forum Technical DiscussionReplies: 1Last Post: 06-05-2004, 11:09 AM -

flywheel puller

By leifbert in forum Technical DiscussionReplies: 7Last Post: 05-11-2004, 01:51 PM -

200 chrome bore. sleeve or not to sleeve?

By fisherman in forum Technical DiscussionReplies: 9Last Post: 01-02-2004, 05:20 PM

Likes:

Likes:

Reply With Quote

Reply With Quote