User Tag List

Results 1 to 14 of 14

Thread: Crank to Block Seals

-

01-26-2016, 12:53 PM #1

Crank to Block Seals

Crank to Block Seals

I'm sure this has been discussed but after searching threads until my eyes were crossed I've decided to just ask!!!

Has, or does anyone Plate a V6 Block where the Crank Seals ride?

I ask because I've seen many Blocks with ring wear in these areas!!!!WillySteve Hendricks

20XDC Bullet/Modified Merc 260

295TF Charger/ProMax 225x-Sold!

'83-20' Contender Pickle Fork/Merc 2.4 ModVP BridgePort EFI-Sold!

'85-18' Stratus STV/Merc Hi-Po 2.4 EFI-Sold!

Freedom 240 DLX Fisher Toon/Merc 115

10' Cougar Cub/Merc 25HP On The Bottle!

18" Home Made Tunnel/OS .021XM Outboard on 50% Nitro and Expansion Chamber

-

01-26-2016, 01:38 PM #2

Have never of plating there.If you take your time and clean up the ridge properly,you could run the double thin rings.That in theory gets rid of most of the gap.

-

01-26-2016, 07:52 PM #3

Screaming And Flying!

Screaming And Flying!

- Join Date

- Jul 2002

- Location

- FT WORTH, TEXAS

- Posts

- 8,031

- Thanks (Given)

- 9

- Thanks (Received)

- 146

- Likes (Given)

- 313

- Likes (Received)

- 505

- Mentioned

- 1 Post(s)

- Tagged

- 0 Thread(s)

they are called sealing rings most of the time they are welded and re-machined both half's are sent to a shop who will do it or can Ruck used to do them but he is watching judge judy now days, unless its has some very excessive wear its not a problem

-

01-26-2016, 09:09 PM #4

How many thousandths is considered too much wear?

Azure AZ259, 8.1

-

01-26-2016, 10:27 PM #5

Screaming And Flying!

Screaming And Flying!

- Join Date

- Jul 2002

- Location

- FT WORTH, TEXAS

- Posts

- 8,031

- Thanks (Given)

- 9

- Thanks (Received)

- 146

- Likes (Given)

- 313

- Likes (Received)

- 505

- Mentioned

- 1 Post(s)

- Tagged

- 0 Thread(s)

i dont know ive never had one that was too bad ive rebuilt over 300 motors ive the last 12 years yes some were my own most were customers

-

01-27-2016, 12:55 AM #6

Should those rings be replaced every time a block is separated or is there some standard most go by as far as wear? I've done several of my own through the years and never changed them!

Fine time to ask huh!!!!!

-

01-27-2016, 07:47 AM #7

Look at the face of the ring,if the very fine tooling marks are there and the sides are smooth and not worn they should be good to go.I usually take a stone and ever so slightly dress the top leading edge of the parting line.So there is no chance that it could scrape the bore as it turns.

-

01-27-2016, 09:13 AM #8

We have all heard the story about how these motor's will run with all the crank rings taken out ... Personally , I think that's a "Unicorn" type story ....

But I have taken 3.0L's apart and and found some of the rings broken in three or four pieces and looked to have been that way for a while .

I alway's do the sides of them on a slab of marble , 400 paper and WD-40 in a figure 8 motion . If I find one that's got a rut cut into one side , I'll replace it with another one.

I'd rather have a smooth seating area for the ring to find a new home , rather than have it forced into one that's already there. Most can just be sanded smooth with just your thumb , 320-400 paper and a little elbow grease. It will open the gap a minute amount . Not a big deal because 90$ of the ring is hidden in the rails .

The real issue is when the ring breaks and dig's in .

I prep it , and then weld it back a little higher and wider. The side get's flattened with a carbide burr and then a tootsi roll.

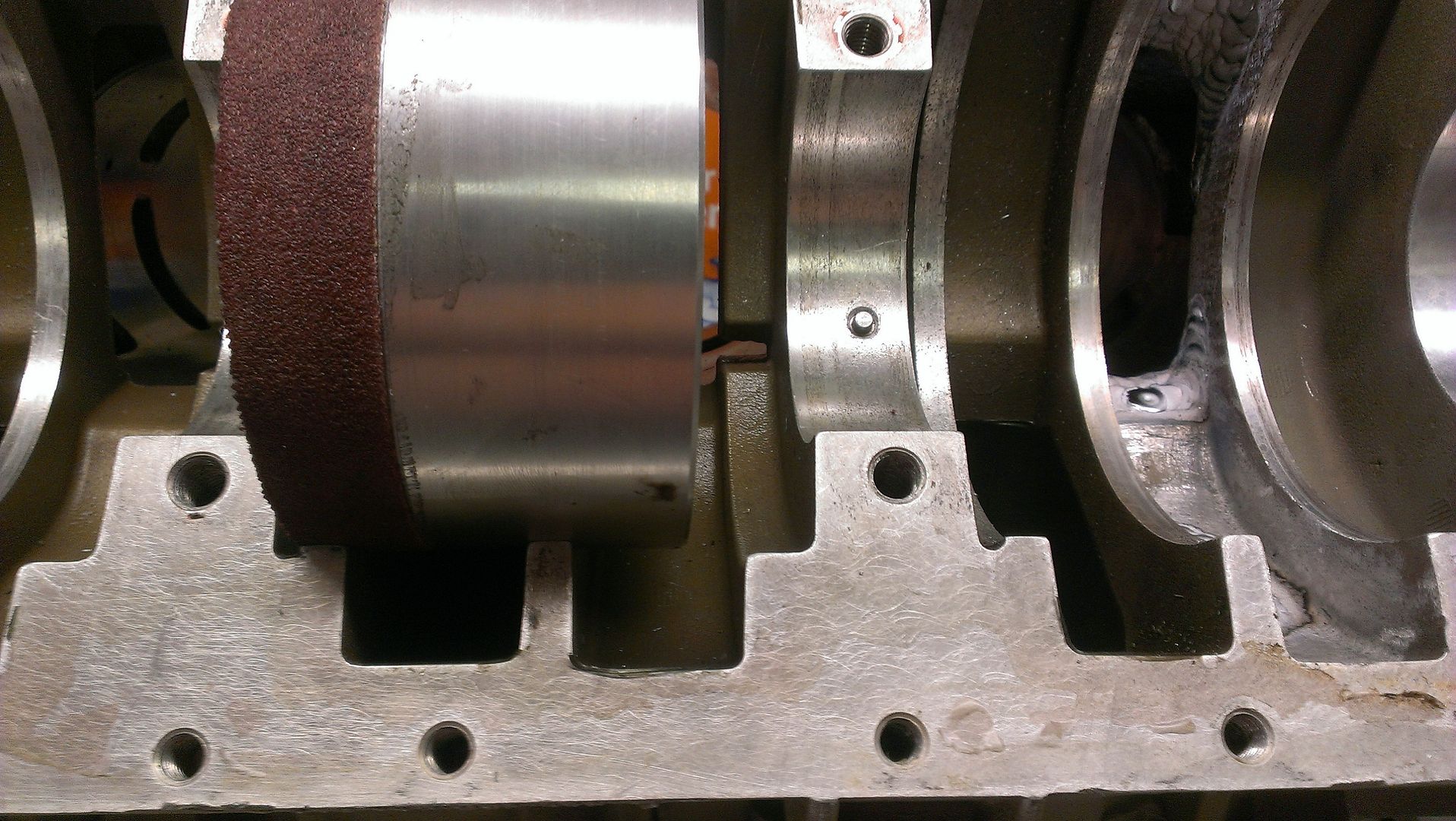

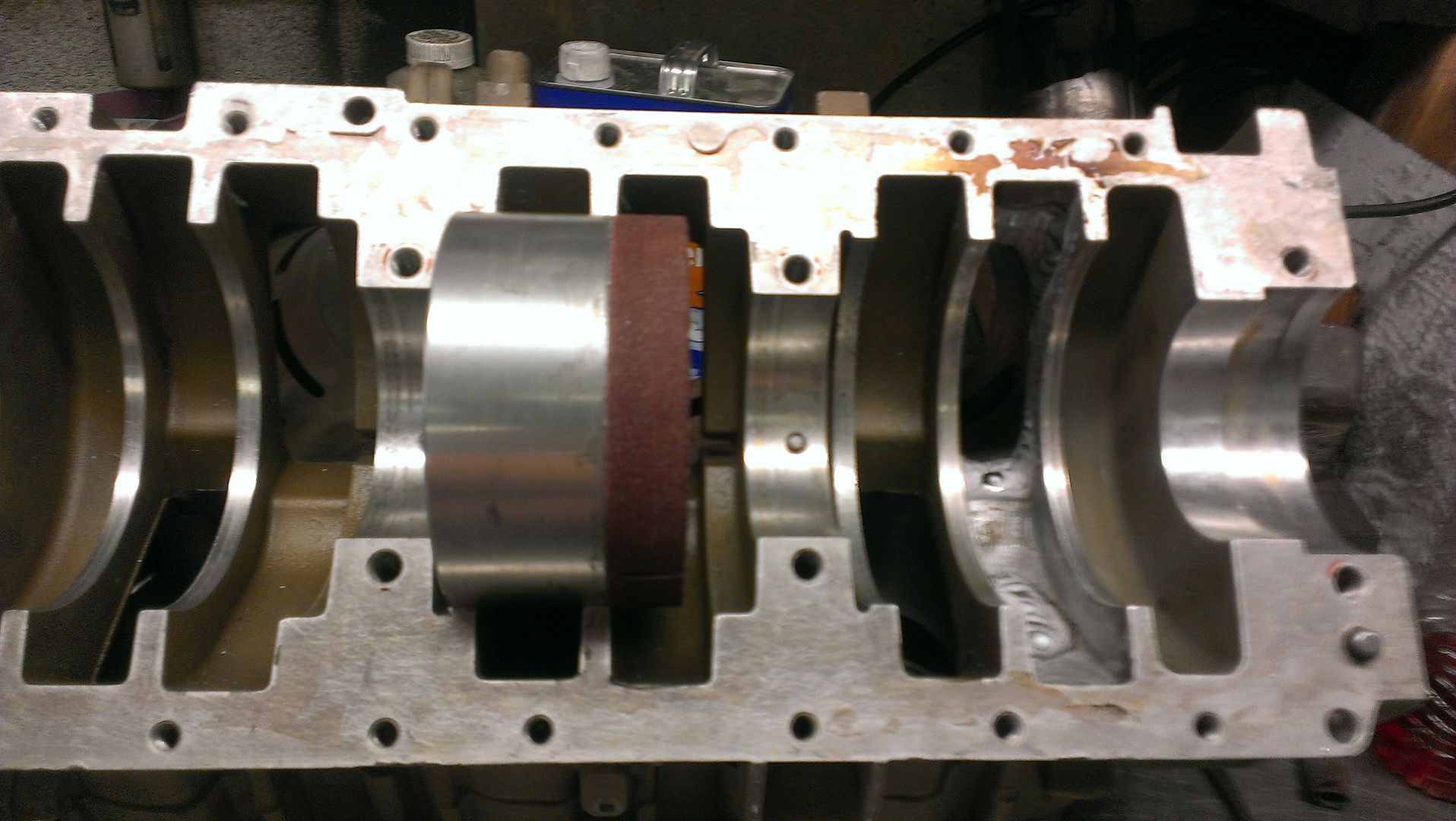

And I made this drum that I spin till it produces a full pattern .

And it's just long enough to reach all of the bore's . And short enough I can put it between two rail's to see if it rock's or sits flat and need's no more attention ..

-

-

01-27-2016, 10:31 AM #9

I've spent close to 40 years of working with Sealing Rings while being in the Automatic Transmission business!! I was Amazed when the Teflon Rings hit the market and figured they would never hold up.....used to chunk'em in favor of the old Cast Iron, Steel and Plated Aluminum Rings!

After a few years I was tearing down units with many thousand miles and finding not only that the Teflon had held up well, but that there was not as much Ring Groove Wear on their prospective Cyls!!!!

Another Fact about Teflon Rings and prolly the reason why they are easier on the bores they run in is that the Ring blows out against the bore and the shaft rotates on the Ring! This causes the Ring to have a solid contact with it's Bore or Cylinder The fluid pressure seeping around the ring keeps it lubricated enough to give the Teflon a good wear characteristic within it ring groove!!!

Also the units that came in burnt to a crisp from overheating....Teflon made the journey....all else failed!!!!

Kinda gives you food for thought huh!!!WillySteve Hendricks

20XDC Bullet/Modified Merc 260

295TF Charger/ProMax 225x-Sold!

'83-20' Contender Pickle Fork/Merc 2.4 ModVP BridgePort EFI-Sold!

'85-18' Stratus STV/Merc Hi-Po 2.4 EFI-Sold!

Freedom 240 DLX Fisher Toon/Merc 115

10' Cougar Cub/Merc 25HP On The Bottle!

18" Home Made Tunnel/OS .021XM Outboard on 50% Nitro and Expansion Chamber

-

01-27-2016, 05:42 PM #10

Screaming And Flying!

Screaming And Flying!

- Join Date

- Jul 2002

- Location

- FT WORTH, TEXAS

- Posts

- 8,031

- Thanks (Given)

- 9

- Thanks (Received)

- 146

- Likes (Given)

- 313

- Likes (Received)

- 505

- Mentioned

- 1 Post(s)

- Tagged

- 0 Thread(s)

charley you are correct there are lots of storys, nice tooling you built mister i see sealing rings on some cranks and some others are not machined for the ring same v6 merc motas leave off a couple compared to early 9 ring cranks and late 300 drag/280 9 ring some 260's have only 7 rings , promaxs have 7 some 2.4 have 8 rings so with the same configuration on crank block whats the deal,also what about the deal of pig putty on the oiler slot and hole then it right up against a bearing that reduces crank case pressure in that hole because the bearing aint going to hold any pressure in that hole so it has more area and same for other center main dont add up to this old fart

-

WillySteve liked this post

WillySteve liked this post

-

01-27-2016, 05:59 PM #11

Team Member

Team Member

- Join Date

- Apr 2014

- Location

- nj

- Posts

- 520

- Thanks (Given)

- 1

- Thanks (Received)

- 19

- Likes (Given)

- 2

- Likes (Received)

- 126

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Please show the side of the drum , thanks for the tips

-

01-27-2016, 08:40 PM #12

Is there any concern to how deep the grooves are in the block and would that affect the end gap of the sealing rings?

-

01-28-2016, 03:14 PM #13

I've built a bunch of Powerglides. The high HP one's now use a ringless input and a bushing in the stator support tube to keep the cooler circuit charged. But yes , on lower HP glides I use Teflon input shaft and low gear survo rings ...

I think the shape of the slot and distance to the case wouldn't lend itself to a soft ring ... but maybe a square one...

The lower ball bearing and end cap holding it in place are the trust surfaces. If the ring is caught in a groove , then it also becomes a thrust face and starts to wear one one side. I think I could do with a little extra gap , in favor of a little extra friction. And as Tex eluded to , Merc and engine builders have run all sort's of combinations. I wouldn't over think it ...

-

WillySteve liked this post

WillySteve liked this post

-

01-28-2016, 07:34 PM #14

I can assure you that I'd try square cut Teflon crank rings on a V6 Merc if I could find'em the rite dimensions....I've never seen any long or deep enough though.

I've cut many that were oversized length wise and used'em religiously in my Drag Race Tranny's.....had great results with'em. The depth and width is critical but they can always be cut down in length if they're too long.

Wonder if the Mercury boys have played with'em since they're so much cheaper vs. metal rings???

Similar Threads

-

ACES & Crank seals

By scott reierson in forum Technical DiscussionReplies: 8Last Post: 11-06-2015, 05:28 AM -

merc 1500 l6 reed block / labrinth seals

By Good4nothing in forum Technical DiscussionReplies: 13Last Post: 08-30-2013, 11:02 PM -

crank seals

By 15smokey15 in forum Technical DiscussionReplies: 2Last Post: 12-01-2006, 07:31 AM -

Help - How do you check crank seals

By 86vintage in forum Technical DiscussionReplies: 0Last Post: 05-28-2006, 08:15 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote