User Tag List

Thanks: 0

Thanks: 0

Results 1 to 15 of 19

-

08-14-2015, 11:50 PM #1

Member

Member

- Join Date

- Mar 2013

- Location

- mobile Al

- Posts

- 97

- Thanks (Given)

- 3

- Thanks (Received)

- 1

- Likes (Given)

- 20

- Likes (Received)

- 5

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

225 Block damage. Can this be repeated?

Repaired*

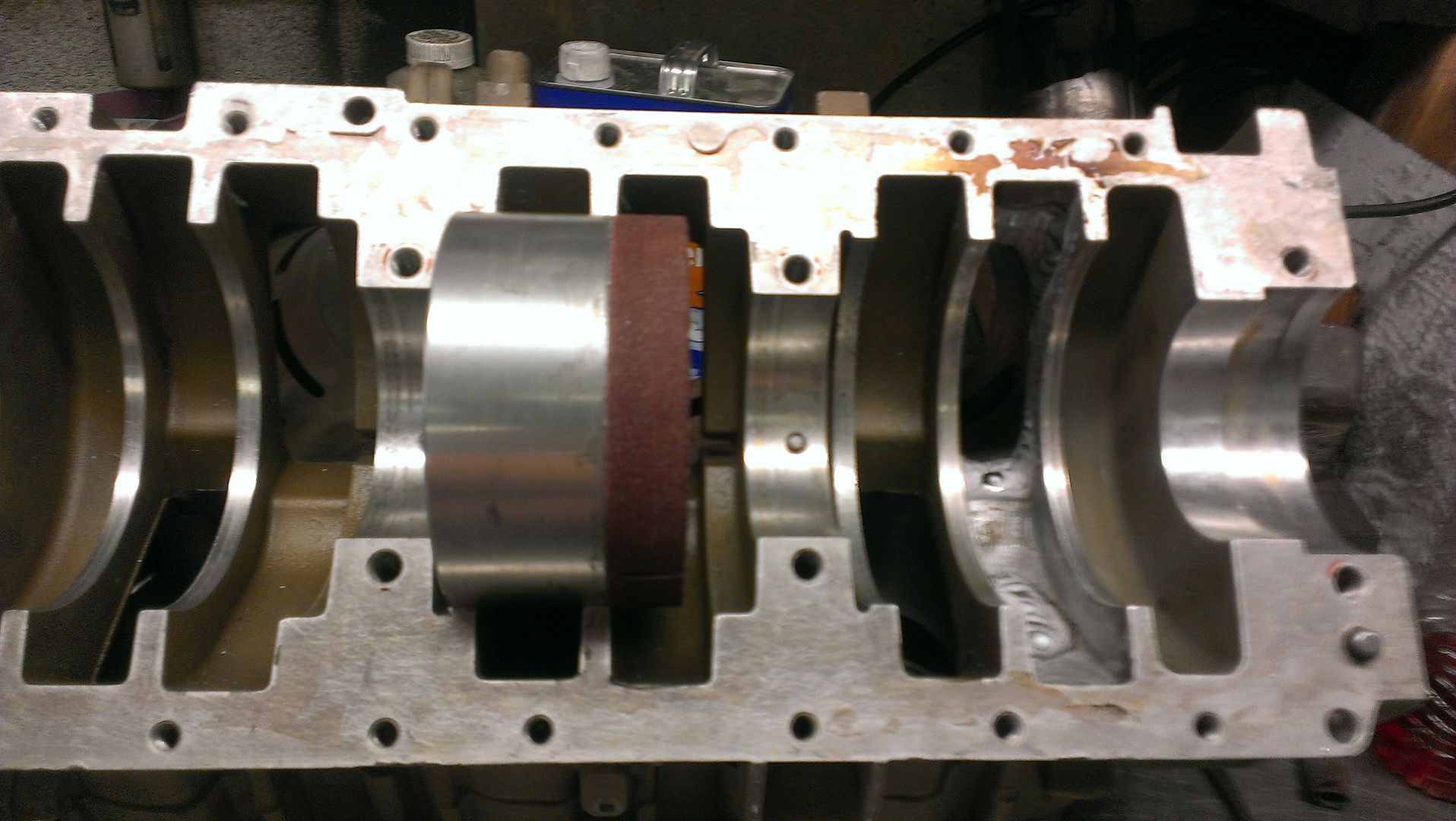

Take a look. The crankshaft was in two pieces. It scarred some of the areas where the crankshaft sits. I've found a crankshaft to use. Not sure about the block. I'm very disappointed and can't spend a whole lot more into this motor. I took a gamble and apparently lost buying this motor.Last edited by dondante; 08-14-2015 at 11:53 PM.

-

08-14-2015, 11:50 PM #2

Member

Member

- Join Date

- Mar 2013

- Location

- mobile Al

- Posts

- 97

- Thanks (Given)

- 3

- Thanks (Received)

- 1

- Likes (Given)

- 20

- Likes (Received)

- 5

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

BTW. If can be welded I have a good friend who owns the largest machine shop in my area and could get the work done pretty cheap.

-

08-15-2015, 06:53 AM #3

Can it be be made to run.probly,but it would take a craftsmen engine builder to fit the new crank.The one ring land is scarred badly,looks like it could be made to seal,but will be a little big.The other lands are worn as well and would require fitting.The only way to know for sure is the builder would have to be there,and work with it a while before he knew for sure.

-

08-15-2015, 08:30 PM #4

I would not worry out of measure about this. Of course the performance would be affected but if you want to run this baby for a while, I would. My tewo cents.

Glastron GT 150 W OMC 140

Glastron GT150 w OMC 235

Hydrostream Vision with 2.0l 135

Hydrostream HST w 3.0L 225

I know two things that are infinite, the Universe and Human's Stupidity, although I am not sure about the first one.

-

dondante liked this post

dondante liked this post

-

08-15-2015, 08:35 PM #5

Member

Member

- Join Date

- Mar 2013

- Location

- mobile Al

- Posts

- 97

- Thanks (Given)

- 3

- Thanks (Received)

- 1

- Likes (Given)

- 20

- Likes (Received)

- 5

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Thanks. My machine shop wizard said he can clean them up.

I've also been told by two rebuild experts that as long as the main bearings seal up that it will be fine. I've also been told that some people don't even use seal rings on the crank. Gonna hope for the best and see what happens. I'll clean it up and replace the seal cranks.

-

texasvector liked this post

texasvector liked this post

-

08-15-2015, 08:41 PM #6

these rings are meant to ''isolate'' the pulsing within the different cylinder ( adjacent ones ') they are useful because, TMO' you'd get a lean condition If you do not use them I might be wrong but according to physics laws, pulsing from the adjacent cylinder would lean the mix of the one....

Glastron GT 150 W OMC 140

Glastron GT150 w OMC 235

Hydrostream Vision with 2.0l 135

Hydrostream HST w 3.0L 225

I know two things that are infinite, the Universe and Human's Stupidity, although I am not sure about the first one.

-

dondante liked this post

dondante liked this post

-

08-15-2015, 10:18 PM #7

Member

Member

- Join Date

- Mar 2013

- Location

- mobile Al

- Posts

- 97

- Thanks (Given)

- 3

- Thanks (Received)

- 1

- Likes (Given)

- 20

- Likes (Received)

- 5

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Well I think I'm lucky because the damage is on the one after the lower center main bearing which also seals. So I don't think it effects anything at all.

-

08-15-2015, 11:11 PM #8

An old Stock Eliminator racer told me , they wont let ya do nothin to make any power , so ya gotta do everything ya can to keep from losin what ya got.

With that being said . The sealing rings get happy running in their grooves and will over time dig a small groove in the blocks register. Maybe not so bad if you use the same crank and rings . But if you change changing parts , the sealing rings may or may not fit exactly in the same spot. Now perhaps that stuff is forced to find a new home during an extended break in period , but to me ,it will always produce a bit of parasitic drag.

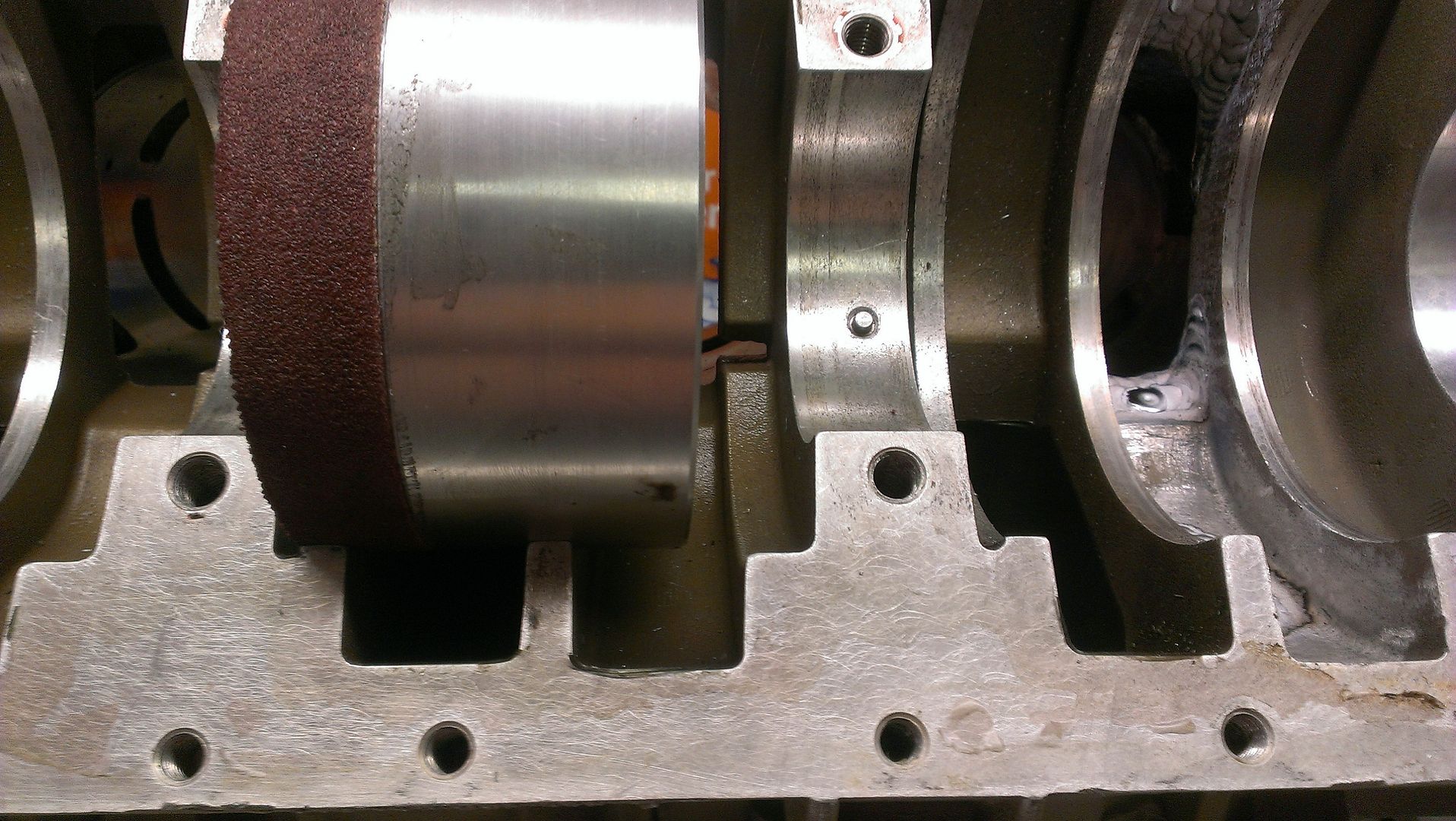

I made this drum . If I am welding anywhere on the outside or down a cyl bore I drop it in where two rings are in contact and bolt the case's together.

If it's one I have to fix

I turn the drum around and use the side that has a recess cut into it and has strips of old belt's from the sander . gets rid of the high spots on either fixed area's or old blocks that have high mileage grooves cut in them ...

-

dondante liked this post

dondante liked this post

-

08-15-2015, 11:49 PM #9

Member

Member

- Join Date

- Mar 2013

- Location

- mobile Al

- Posts

- 97

- Thanks (Given)

- 3

- Thanks (Received)

- 1

- Likes (Given)

- 20

- Likes (Received)

- 5

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Snazzy. I like. Yes, I will have to use a new crankshaft.

-

08-16-2015, 02:19 AM #10

Member

Member

- Join Date

- Mar 2013

- Location

- mobile Al

- Posts

- 97

- Thanks (Given)

- 3

- Thanks (Received)

- 1

- Likes (Given)

- 20

- Likes (Received)

- 5

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

You should totally rent that tool to me.

-

08-17-2015, 07:08 AM #11

Don ,

Bad part is , I use it just about every day .....

Good new's is , I gave ya the key's to the kingdom ...

-

08-17-2015, 07:43 AM #12

Member

Member

- Join Date

- Mar 2013

- Location

- mobile Al

- Posts

- 97

- Thanks (Given)

- 3

- Thanks (Received)

- 1

- Likes (Given)

- 20

- Likes (Received)

- 5

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

I'd love to know the specs on that drum. Very nifty tool you made.

-

08-17-2015, 07:49 AM #13

5000 RPM

5000 RPM

- Join Date

- Dec 2007

- Location

- Alma, Ar

- Posts

- 168

- Thanks (Given)

- 0

- Thanks (Received)

- 0

- Likes (Given)

- 15

- Likes (Received)

- 5

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Just built a 2000 225 Merc that had the same condition from a 2 piece crank. There is probably a little more land left there than you think. Mark it with a black magic maker and take a small die file and work the burs off. The black marker will keep you from going too far. Mine is running great so far as I only have about 5 hrs on it. Good luck, Jim

-

08-17-2015, 08:26 AM #14

Member

Member

- Join Date

- Mar 2013

- Location

- mobile Al

- Posts

- 97

- Thanks (Given)

- 3

- Thanks (Received)

- 1

- Likes (Given)

- 20

- Likes (Received)

- 5

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Thanks mold. I've see "die file" used several times. Not too sure what sort of file you guys are speaking of.

-

08-17-2015, 08:33 AM #15

Member

Member

- Join Date

- Mar 2013

- Location

- mobile Al

- Posts

- 97

- Thanks (Given)

- 3

- Thanks (Received)

- 1

- Likes (Given)

- 20

- Likes (Received)

- 5

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

This?

Neiko 10032A Neiko 10032A 1/4-Inch Shank Double Cut Carbide Rotary Burr Set, 8-Piece, , https://www.amazon.com/dp/B0016KD0H8..._IiE0vb5TPE5CJ

Similar Threads

-

stv rr damage...........

By BRB in forum General Boating DiscussionReplies: 2Last Post: 08-05-2009, 11:48 AM -

Here's the damage - what are my options?

By dma251 in forum General Boating DiscussionReplies: 30Last Post: 02-11-2006, 09:23 PM -

Minor block damage from removing head, help!

By Pete Keppler in forum Technical DiscussionReplies: 12Last Post: 04-18-2005, 11:09 AM -

2.5 Block damage

By bullet19 in forum Technical DiscussionReplies: 2Last Post: 12-27-2003, 08:02 PM -

jsre block work & UPS damage

By check88 in forum General Boating DiscussionReplies: 20Last Post: 03-18-2003, 08:27 AM

Likes:

Likes:

Reply With Quote

Reply With Quote