User Tag List

Results 1 to 15 of 17

Thread: Cylinder Head Machine Question

-

11-13-2019, 10:17 AM #1

Cylinder Head Machine Question

I want to start off by saying this is the formula I used in the past to acquire correct cc's on my drag bike heads so it may be incorrect for marine 2 stroke applications. To learn how much material to remove to achieve the desired cc's I practiced this method with good results. I personally always installed the spark plugs I would be using to fill the void before starting. I then found true zero on the head ( setting the head dead level) and injected the desired cc's of liquid into the head. With the liquid static and not moving I would scribe the water line onto the casting. I then used calipers to find how much material was between the scribe mark and head deck. This would give me a starting point to shave for the cc's I wanted. I also measured each cylinder just to make sure they were close, and most times added the 4 and divided by 4 for the average. Is this an acceptable way to get started on marine 2 stroke heads as well? Thanks

Respect no wake zones!!! Evinrude guys need a place to race too.

-

11-13-2019, 11:51 AM #2

5000 RPM

5000 RPM

- Join Date

- Apr 2011

- Location

- Long Beach

- Posts

- 319

- Thanks (Given)

- 0

- Thanks (Received)

- 7

- Likes (Given)

- 14

- Likes (Received)

- 23

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

The correct way to CC heads is to use a piece of glass or plexyglass to drip your water into and when water makes contact with the whole underside of the glass...it's full. Surface tension and the "cap" on an open bath of water will give you screwy results.

You can do some quick math to get you in the ballpark...measure the OD of the combustion chamber in the head, pi r sq to determine the area, then multiply that by the depth of cut, but with tapered chambers, this is a ballpark at best.

I typically test first, then take off .020" and test again. That gives me an idea of how much farther to go. Keep in mind, the more you take off, the greater the gain per cut.

-

KIRCHNER thanked for this post

KIRCHNER thanked for this post

-

11-13-2019, 12:20 PM #3

Right on, I understand the correct method to get total cc's on a head. I was just throwing out the method I use to get close to the mark before doing a total cc test.

Respect no wake zones!!! Evinrude guys need a place to race too.

-

11-13-2019, 06:44 PM #4

Water crawling up the wall is known as the "meniscus layer". While it will throw off your final number, it will do so on the low side. leaving a bit of a built-in safety margin.

https://www.usgs.gov/special-topic/w...center_objects

Most outboard's have a "top-hat" type chamber, meaning that the walls are parallel. So each cut will remove the same volume from beginning to end. Keeping in mind that the quench pad be it a flat recess or at an angle will need to be cut back in.

The short answer is for most .007 to .010 will equal 1 cc . Which is a useful "rule of thumb" while machining. It is far better to know the compression before taking the motor apart , target compression you are looking to arrive at and then use the bore, stroke, rod length, exhaust port height and deck height to do a before and after "trapped volume" number.

-

11-13-2019, 06:57 PM #5

Right on, thanks for the feedback. I used to use my above method just to get close, then I would use the math to determine the remaining .000 that needed to be cut. Good info Chaz and lbh

Respect no wake zones!!! Evinrude guys need a place to race too.

-

11-13-2019, 08:30 PM #6

-

TNRoostertail liked this post

TNRoostertail liked this post

-

11-13-2019, 08:44 PM #7

Whats the difference between a 2.4 1 piece and a 2.0 1 piece if any? Thanks

Respect no wake zones!!! Evinrude guys need a place to race too.

-

11-13-2019, 09:42 PM #8

-

mach351 liked this post

mach351 liked this post

-

11-13-2019, 10:32 PM #9

Screaming And Flying!

Screaming And Flying!

- Join Date

- Jul 2002

- Location

- FT WORTH, TEXAS

- Posts

- 8,031

- Thanks (Given)

- 9

- Thanks (Received)

- 146

- Likes (Given)

- 313

- Likes (Received)

- 503

- Mentioned

- 1 Post(s)

- Tagged

- 0 Thread(s)

most of the time smaller cylinders gets smaller diameter combustion chambers but not always i just pulled a set of a late model 2.0 fat block it had 787 C2's on it which have 2.1/8 diameter chamber on them (approx) i also have set of 488 C4 that have 2/18 combustion chamber on them and its not the first time i have had same casting number on heads that have different diam. combustion chambers i did not cc them they may have been deeper to get the 38cc they were supposed to be but its Mercury so some time its a surprise. the two piece heads had 31/8 and 33/8 cast in them 2.0 and 2.4 which was visible from the out side

-

11-14-2019, 12:44 PM #10

Right on, thx Tex

Respect no wake zones!!! Evinrude guys need a place to race too.

-

11-14-2019, 05:47 PM #11

Screaming And Flying!

Screaming And Flying!

- Join Date

- Dec 2001

- Posts

- 9,502

- Thanks (Given)

- 23

- Thanks (Received)

- 271

- Likes (Given)

- 191

- Likes (Received)

- 1976

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

The Hemi heads.... the flash point is close tha surface.... heat loss.... the flat tops the spark is closer to the gas charge........put in gap plugs... the flash point is closer to the max gas..... JMO

-

11-14-2019, 07:25 PM #12

-

11-14-2019, 09:30 PM #13

Screaming And Flying!

Screaming And Flying!

- Join Date

- Dec 2001

- Posts

- 9,502

- Thanks (Given)

- 23

- Thanks (Received)

- 271

- Likes (Given)

- 191

- Likes (Received)

- 1976

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

You missed what I was saying....Early merc heads were hemi style......later were flat....and the spark closer to the mass of charge.....IMO better .... that's why merc went that way.....and later motors had gap plugs..... closer to the center of the charge......than surface plugs.....I don't know if it makes a diff..... just what merc did it improve their motors.....the old hemi heads last longer.... as they are die cast.... the one peace rot out........if old salty....JMO

-

TNRoostertail liked this post

TNRoostertail liked this post

-

11-16-2019, 12:52 PM #14

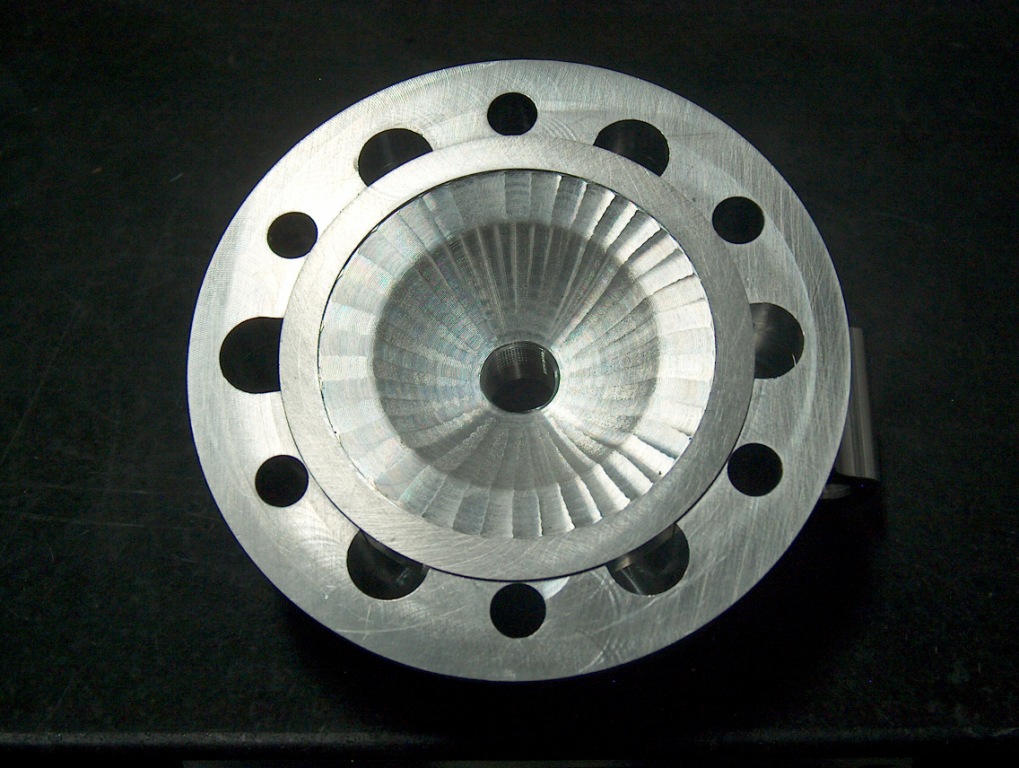

I'm a fan of the "half a golf ball" (hemi) combustion chamber.

The reason they got away from them is , because that design is less tolerant of low octane fuel and ignition timing than a "top hat" style chamber.

maybe too much of a good thing on this vintage chamber .. LOL , they brought it up to the 1970's

I did a few sets of weld-up's. I think anytime you can make the same or more power on less timing and fuel load ... your heading in the right direction ...

These old "over the hill to grandmother's house we go" crossflows, always seem to run real "dirty" . I never had one, anybody know how much timing they needed ?

To get the party started early enough to try and burn all the charge ...I would imagine ... a lot.

Slugs look heavy too .... Built-in rev limiter ...

I'm sure they made good torque off the bottom, but fell off early ...

Some of the "new tech" idea's make sense , others look pretty bizarre ...

Mild ....

To wild ....

Yamaha made wide use of the Toroidal chamber , with good luck ...

-

TNRoostertail thanked for this post

TNRoostertail thanked for this post

-

11-16-2019, 03:10 PM #15

Chaz. Can u weld up sum 2.5 heads and make em hemi like old 2 piece. Will that still work?

Similar Threads

-

head gasket and cylinder head

By drtyTshrt in forum Technical DiscussionReplies: 1Last Post: 03-26-2017, 08:47 PM -

OMC Tech: Evinrude V8 Cylinder Head Question

By Westtexan in forum Technical DiscussionReplies: 11Last Post: 03-14-2017, 09:52 AM -

1985 Johnson 140 cylinder head question

By 1987Bee in forum Technical DiscussionReplies: 6Last Post: 01-12-2017, 06:53 PM -

Mercury Tech: Cylinder Head Question 2.4-200

By dwiggl in forum Technical DiscussionReplies: 4Last Post: 07-08-2011, 02:42 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote