User Tag List

Thanks: 0

Thanks: 0

Results 1 to 15 of 31

Thread: 2.4 bridgeport rebuild advice

-

04-14-2014, 02:46 PM #1

New Member

New Member

- Join Date

- Apr 2012

- Location

- texas

- Posts

- 4

- Thanks (Given)

- 0

- Thanks (Received)

- 0

- Likes (Given)

- 0

- Likes (Received)

- 0

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

2.4 bridgeport rebuild advice

I am rebuilding a 2.4 liter Bridgeport efi and looking for advice on what or what not to do. It is on 85 Sleekcraft SST. From what I have found it is said to be a 900 pound boat. My plans for the rebuild are:

Block

The block would be made into a tubed 2.4.

Clean up casting in the rod slots and inside the block.

Fill in the area of the oil pump gear slot to increase crank case pressure. (this is bridge port so there is no gear there)

Drill extra cooling holes in block and add rubber cooling diverters to #3 and #4 piston cooling passages. Already have these at #5 and #6.

Possible redoing nikasil of the block.

What size tube 1/2" ID copper or I/2" OD aluminum fuel line for tubing the block?

Should I have any porting done to the block? I know I will have to redo nikasil on block.

Where should block stuffing be done and how much? I have not been able to find much info on this.

Exhaust chest

Gasket match exhaust port on bottom of block.

Cut exhaust chest to 225 pro max specs and polish exhaust chest.

Rods 636-8118 and factory Mhale pistons

Remove casting lines from rod. Have them shot peened and balanced.

Convert rods to top guided. Remove 0.100 from crank journal end of rod and use the thick washer from early 1990's 260 for spacer between piston and small end of rod or will I need the thinner washer also to correct the spacing?

SPS rod bolts will I need to modify the rods for the bolts to work?

Lightened wrist pins

D port or window port piston?

What size should I redrill the finger port holes?

Should I drill extra finger port hole or slot it on piston?

Crank

Crank and rotating assembly balanced.

Remove seal ring above bottom main bearing

Heads

Planning on compression of 145 psi. What cc should heads be?

Front half

Remove 0.50 from front reed plate.

Use reed cage 7 petal.

Should I use 1" spacer on intake?

Planning on brucato acu and svs.

Getting injectors cleaned.

Sorry for the book. Just trying to give as much information as possible. Thanks in advance for any advice or suggestions.

JamesLast edited by rude sleekcraft; 04-14-2014 at 02:51 PM.

-

04-18-2014, 09:58 AM #2

5000 RPM

5000 RPM

- Join Date

- Apr 2013

- Location

- Canada

- Posts

- 511

- Thanks (Given)

- 2

- Thanks (Received)

- 1

- Likes (Given)

- 18

- Likes (Received)

- 25

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

your going to tube a 2.4l?

subscribed

subscribed

-

04-18-2014, 10:20 AM #3

There goes another good Bridgeport block. Modify, run, boom.

Why not just get a 300 Drag, or modify a 260 or 280 for more potential?

Bridgeports have a reputation for poor reliability, but the fact is, they nearly run forever if you leave them stock.'89 Hydrostream Vegas XT, '90 Merc 2.4 Bridgeport PCU EFI

My YouTube videos________My Flickr photo gallery

http://www.facebook.com/profile.php?id=1706097519

-

04-18-2014, 02:44 PM #4

5000 RPM

5000 RPM

- Join Date

- Apr 2013

- Location

- Canada

- Posts

- 511

- Thanks (Given)

- 2

- Thanks (Received)

- 1

- Likes (Given)

- 18

- Likes (Received)

- 25

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

why not tube a 2.0l block,, cheaper to replace if/when you make a mistake.. and a more forgiving block in general

-

04-18-2014, 05:12 PM #5

Waste of time on a sleekcraft sst. You'd be far ahead of the game to find a 225 pro max drop on. if you had a true 600 lb hull that aired out you would have a good idea. The death of most BP's was the sh*tty ecu's crapping out, or the ol' lean is mean tuning procedure.

-

04-18-2014, 10:52 PM #6

5000 RPM

5000 RPM

- Join Date

- Jan 2013

- Location

- SE MN

- Posts

- 866

- Thanks (Given)

- 44

- Thanks (Received)

- 23

- Likes (Given)

- 145

- Likes (Received)

- 63

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Please excuse my ignorance, but what is "tubing"?

-

04-19-2014, 12:55 PM #7

5000 RPM

5000 RPM

- Join Date

- Apr 2013

- Location

- Canada

- Posts

- 511

- Thanks (Given)

- 2

- Thanks (Received)

- 1

- Likes (Given)

- 18

- Likes (Received)

- 25

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

-

04-19-2014, 01:08 PM #8

5000 RPM

5000 RPM

- Join Date

- Jan 2013

- Location

- SE MN

- Posts

- 866

- Thanks (Given)

- 44

- Thanks (Received)

- 23

- Likes (Given)

- 145

- Likes (Received)

- 63

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Thanks for the reply.

-

04-19-2014, 01:34 PM #9

-

Laseraddict liked this post

Laseraddict liked this post

-

04-19-2014, 01:44 PM #10

5000 RPM

5000 RPM

- Join Date

- Apr 2013

- Location

- Canada

- Posts

- 511

- Thanks (Given)

- 2

- Thanks (Received)

- 1

- Likes (Given)

- 18

- Likes (Received)

- 25

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

how mach psi should a stock mod vp have?

-

04-19-2014, 05:57 PM #11

Stock Bridgeport, 22 pitch Yamaha, pulled to 8000 rpm.

Heavy 20 foot boat.

http://www.youtube.com/watch?v=_EqEesV0Ap0'89 Hydrostream Vegas XT, '90 Merc 2.4 Bridgeport PCU EFI

My YouTube videos________My Flickr photo gallery

http://www.facebook.com/profile.php?id=1706097519

-

04-21-2014, 12:06 AM #12

tuber.....

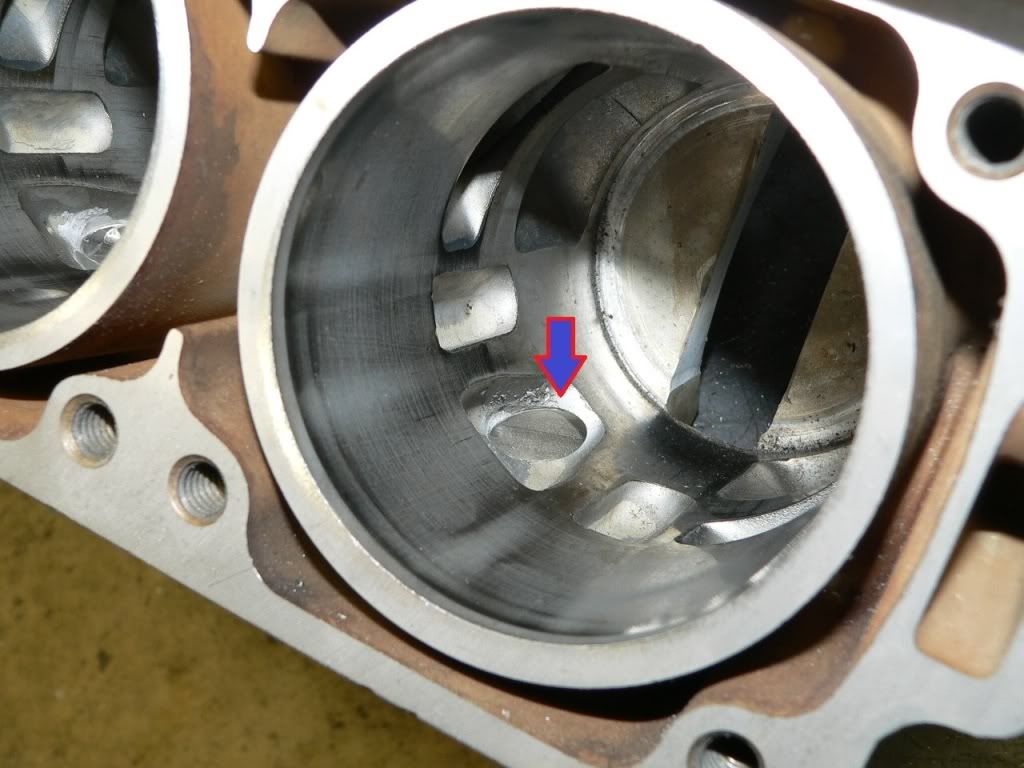

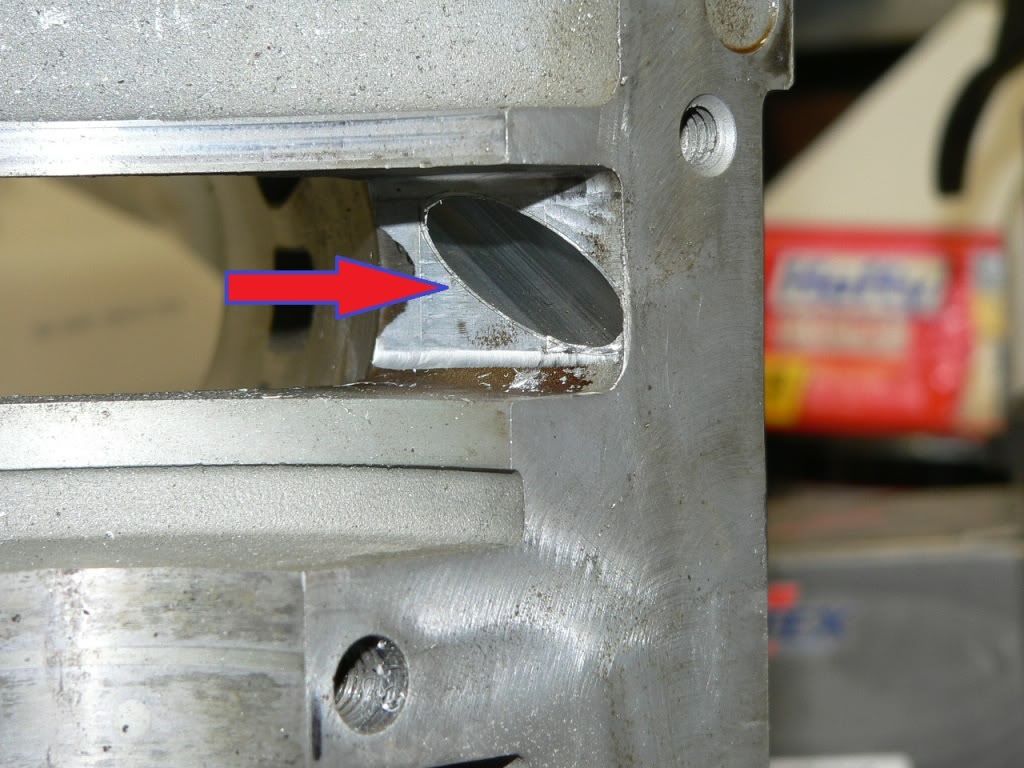

Tubing is making a direct path for a air/fuel charge to go from the crank case to the booster port.

This allows a large portion of the fuel charge to go around the piston instead of through it similar to a

2.5 "behind the liner" engine.Here are some pics of my tubed Bridgeport using 1/2 aluminum tubes.

I have done several 2.4 tubers. I used the laser injection off of a 225 promax instead of the crankcase

injection and it done great.

James Perry

James Perry

-

rgsauger liked this post

rgsauger liked this post

-

04-21-2014, 07:54 AM #13

5000 RPM

5000 RPM

- Join Date

- Apr 2013

- Location

- Canada

- Posts

- 511

- Thanks (Given)

- 2

- Thanks (Received)

- 1

- Likes (Given)

- 18

- Likes (Received)

- 25

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

-

04-21-2014, 08:06 AM #14

Seen James's work on some of Bobby's blocks and believe me he is very, very good...........

-

04-21-2014, 09:58 PM #15

Thank you both for the kind words....

James Perry

Likes:

Likes:

Reply With Quote

Reply With Quote