User Tag List

Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Results 1 to 4 of 4

-

08-16-2009, 09:07 AM #1

Junior Member

Junior Member

- Join Date

- May 2008

- Location

- Southern California

- Posts

- 10

- Thanks (Given)

- 0

- Thanks (Received)

- 0

- Likes (Given)

- 0

- Likes (Received)

- 0

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Cracked aluminum transom; need help for repair/reinforcement

Hello everyone,

This boat has been giving me some grief lately. Mainly because of the longshaft motor that I have. I know I should sell it and get a shortshaft 40-50, but right now I do have the longshaft and have been working around it. In the process I'm sure that is why my transom cracked. I had to use a jackplate to raise the motor for the correct height. It was working for a while but when I was out yesterday I noticed the crack in the transom as I was motoring back in.

Here are pics of the crack. If anyone can please share on any reinforcement tips and how anyone repaired a cracked aluminum transom. Thanks everyone.

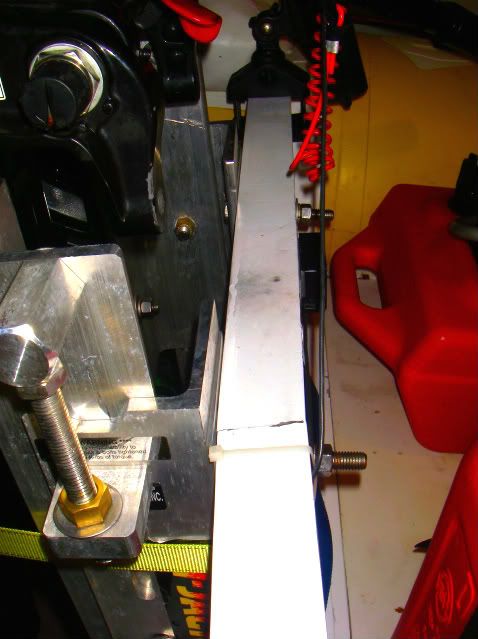

Here's the current setup;

topview crack;

closeup view crack;

underside view crack;

thanks again,

Jeff

-

08-21-2009, 07:40 PM #2

Take it to a welding shop. Aluminum can be welded and the transom reinforced. I would remove the engine, jack plate, as well as the fuel tanks.

-

01-13-2010, 01:54 PM #3

A part of the problem is you have lifted the motor and increased the torq of the motor pushing the boat onto the top part of the transom , Welding is just going to break again if not the weld then close to it , The transom need to be redesigned and rebuilt using some decent materials ! Also because its a inflatable it should have the tube attachment area increased in size and refabricated back on again , The twisting of the transom will get transfered to the tube and you will end up with yet another problem of tearing the tube , it needs to be increased in size to transfer the new loading better . Do you have a tube pressure gauge and know what the recomended running pressure is surposed to be ? One of your valves need to be a preset blow off

so it the boat sits in the sun it wont over pressureize and streach the tubes out of shape .

When you change something other things change as well .If you have increased the hp thats just a start of your ongoing problems , by jacking the motor you have changed the possition and increased the torq on the transom and all this is going to be tranfered out to the tube so it will need atention as well .!!!!

I have worked on Surf life saving inflatebles for a longtime and seen some of there problems !!Last edited by tunnels; 01-13-2010 at 02:18 PM.

Messing round with boats is fun !! the learning never stops ,even after more than 30 years there's always something new happening somewhere !

BUT somethings never change and some problems never go away and just keep reoccurring !!

BUT somethings never change and some problems never go away and just keep reoccurring !! so moved into Composite Forensics , Now that something completely new !!

so moved into Composite Forensics , Now that something completely new !!

-

02-14-2010, 06:02 PM #4

Junior Member

Junior Member

- Join Date

- Dec 2007

- Location

- canada

- Posts

- 8

- Thanks (Given)

- 0

- Thanks (Received)

- 0

- Likes (Given)

- 0

- Likes (Received)

- 0

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

just from appearances the aluminium tubing looks to be very light and what the other fellow saying about having to use a jack plate for this application is all true

the motor is to way to high you have changed the center of gravity for not only the enginering stresses of the transom but also the boat itself.........

you neglected to mention the size motor this rib is designed to carry .......quite an important thing to consider

without testing the metal the photos you provided lead me to believe that you are pushing this rib way beyond the intended limits

these are not stress cracks or metal fatigue........ but rather shear forces at work..........

if you reinforce the transom the forces will be just transferred else where......

just 1 more thing to consider........

failures can be not only expensive but dangerous as well for you and others........... others being the optimum word here

Reply With Quote

Reply With Quote