User Tag List

Results 1 to 15 of 70

-

06-26-2017, 03:30 AM #1

Can i use bust prop as a test prop

Hi all

I have a bust 3 blade prop with 1/4 of one of the blades missing.

Can i bend over the other 2 reaming blades and make some kind of test/club prop out of it?

Only for testing the engine in a barrel ????

-

06-26-2017, 04:01 AM #2

It'd be WAY out of balance. Seals and bearings gone.

I carry a gun because a cop won't fit in my pocket.

1987 Glasstream 15V

1986 Mariner "Tower of Power" 115

-

06-26-2017, 11:27 AM #3

If i were to cut the other 2 blades by the same amount will it work ?

-

06-26-2017, 05:48 PM #4

7000 RPM

7000 RPM

- Join Date

- Feb 2005

- Location

- seattle

- Posts

- 2,654

- Thanks (Given)

- 0

- Thanks (Received)

- 17

- Likes (Given)

- 0

- Likes (Received)

- 33

- Mentioned

- 2 Post(s)

- Tagged

- 0 Thread(s)

buy the test prop. the lower unit is 1000 vs maybe 300.

-

06-26-2017, 07:02 PM #5

6000 RPM

6000 RPM

- Join Date

- Apr 2001

- Location

- Calgary, Alberta

- Posts

- 1,123

- Thanks (Given)

- 21

- Thanks (Received)

- 58

- Likes (Given)

- 341

- Likes (Received)

- 174

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

There are often test props for sale on eBay - going rate is $100-200.

Matt

-

06-26-2017, 07:23 PM #6

Theres ones on ebay for under $49... buy it now price

Last edited by roadkill636; 06-26-2017 at 07:25 PM.

-

06-26-2017, 07:23 PM #7

Yes , of course it will ... someone had to cut the ones for sale didn't they ..

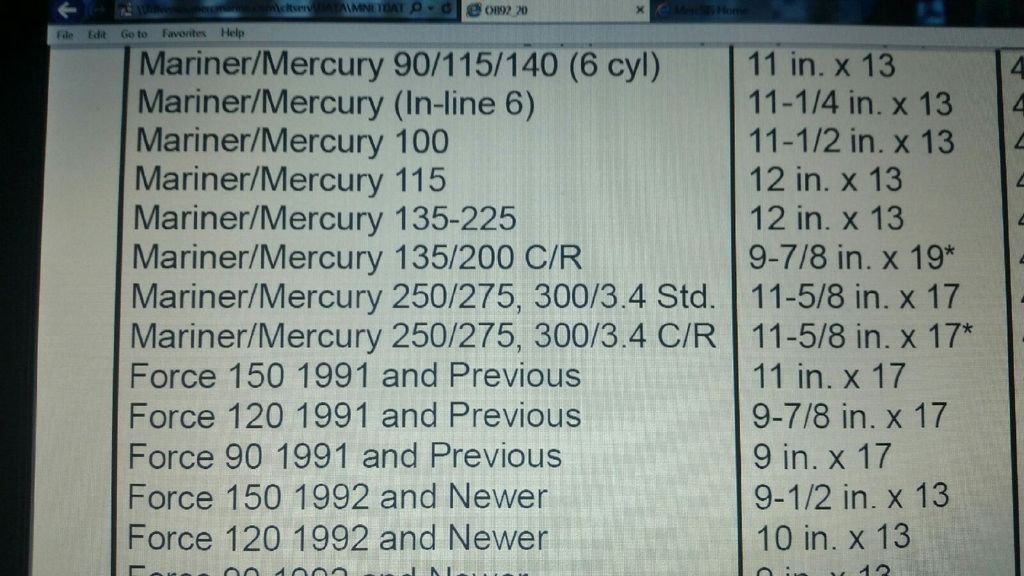

Here is an old service bulletin , find your motor size and cut you "test wheel" accordingly .

I use a piece of poster board to make a template . I mark all three or 4 blades and measure the diameter ... if it's what I'm looking for , then It's good to go ..

-

06-27-2017, 01:52 AM #8

-

06-27-2017, 03:48 PM #9

Andy , the prop has no idea what it's bolted too . All it knows it how much Ummpff it take to turn it .

If you have a 85 horse motor and your prop is a 13" pitch , then you would need to cut the diameter down to 11" .

If you have a 17" then it looks like you will need to be as small as 9" diameter .

Actually that chart shows you a pretty wide spectrum . If your bent prop is hypothetically a 15" then shoot for cutting it to 10" ... you'd be surprised how much 1/4 - 1/2 inch in diameter makes ... And once you cut one and get familiar with it , you'll know right away if a different motor is the dogs bollocks or a mutt ...

-

58Evinrude liked this post

58Evinrude liked this post

-

06-27-2017, 04:56 PM #10

Well said chaz, your bang on the money .

Just go ahead and cut all blades to be as near as you can the same.

if you want to balance it to perfection then go ahead, but I guarantee you will not buy a brand new test prop that is balanced perfectly!!!

and are you going to be putting it on a perfectly balanced set of shafts seals bearings and run it in a special test tank that dont just froff up and s

splash about ? of course not.

your only testing for a short amount of time.

most test props get used on a motor for about 5 mins then get chucked in a corner until needed again.

one of the most abused tools in a outboard shop next to the hammer.

-

06-28-2017, 07:56 PM #11

6000 RPM

6000 RPM

- Join Date

- Apr 2001

- Location

- Calgary, Alberta

- Posts

- 1,123

- Thanks (Given)

- 21

- Thanks (Received)

- 58

- Likes (Given)

- 341

- Likes (Received)

- 174

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Not so fast there PnJ, I'm not convinced you have worked in a shop and are able to accurately comment. At the OMC/Bombadier dealership I worked at, we had an entire set of factory test props and they were used daily - certainly not abused - we had a nice rack to store them in (they are a significant investment). And they are often used for more than 5 min at a time. To diagnose intermittent problems we would often run the motor for quite a while in the tank, working on something else nearby, waiting for it to act up. They are also very useful to put some initial break-in/test time on a powerhead rebuild. We had 4 custom test tanks, with ventilation systems and one had a built in hoist.

That info from Chaz is very interesting, I have never seen that posted before anywhere - thank you Chaz. I now regret spending so much on my own OMC test props - I have three lol.

MattLast edited by MattGreen; 06-28-2017 at 07:59 PM.

-

58Evinrude liked this post

58Evinrude liked this post

-

06-28-2017, 11:19 PM #12

Matt , Ol phillin is a jolly good bloke mate ...

OMC put some effort into their test wheel program . I know they made a bunch of different wheels like this pin drive unit . While you have to buy a few units going in , it doesn't matter where you are in the world you have a known standard .

Talking to a Merc rep whos asks , so you tested that motor with a wheel cut down to 12" .. ? Well no , mine is 12 3/4" , but still the motor wont pull it ... gives them an out , call us back after you have done a proper test procedure ..

The more I look at this thing , the more it looks like a stator out of a hi-stall torque converter ...

-

Slimm liked this post

Slimm liked this post

-

06-29-2017, 12:00 AM #13

6000 RPM

6000 RPM

- Join Date

- Apr 2001

- Location

- Calgary, Alberta

- Posts

- 1,123

- Thanks (Given)

- 21

- Thanks (Received)

- 58

- Likes (Given)

- 341

- Likes (Received)

- 174

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

Exactly

The OMC factory service manuals have a spec for what Rpm a given motor is supposed to spin a given P/N test prop, hence a diagnostic tool to determine overall health of a motor. They even have coresponding left hand rotation test wheels for counter-rotators.

The OMC factory service manuals have a spec for what Rpm a given motor is supposed to spin a given P/N test prop, hence a diagnostic tool to determine overall health of a motor. They even have coresponding left hand rotation test wheels for counter-rotators.

As I understood it, Merc service department encouraged dealers to have propshaft dynos instead, which is why that service bulletin surprised me. These tests props and our 2 mobile test tanks made our shop owner a lot of cash. We'd charge an extra hour for any motor >35 hp that needed a tank test.

Matt

-

06-29-2017, 08:00 AM #14

Sorry matt green , but I think your slightly mis-informed, it is completely understandable to speak like you do because you have

fallen into the ( drum roll) "special tool trap" like so many others have done and will carry on doing as long as we breath.,

I bet you have even been under the hypnotic spell of the Snap-On man too , with his shiny RED tool boxes and super smooth shiny spanners !!!!

Sometimes their spells are a bit weak and can only (blue) point you to the cheaper "special offer" section..

( I think we get music played to us that we can only subconsciously hear, with words like "shiny big red boxes" or "shiny wrenches " ).

I have honestly heard people walk into workshops and say " he must know what he is doing, look at the tools "..... no it realy means he is a mug.

he has been duped into paying out around 10 times more than he needed to.

now back to the serious stuff and this topic.

we all know there can be a huge difference between a prop that comes brand new in a box, than the prop that gets a proper finish. ? Yes .

The brand new in a box prop is not as true as some might think, its a bit out of balance and not even each blade the same pitch, this is

not just on cheapo props, but also on expensive props too.

mercury for example sell a very expensive prop and then have the cheek and audacity to offer a special service to make it good and true ?

So please explain to me how they sell the test wheels so cheap compared to top of the line props that have to be extra worked to be so good.

to make a test wheel and have it the quality of a pro finish prop would be very hard, very time consuming and extremely expensive.

the finish on 99.9% of test wheels is not that good, look at the blades or vanes as they would be called on such a device, they are not perfect.

Look for the casting marks on these wheels , again not so perfect. nothing at all like a technical precision instrument. ( not the ones I have seen)

I wonder what would happen if we were to weigh the test wheels and then check for things like balance and although very hard check for the pitch .

this would then chuck a spanner right into the works as no way are these going to all be identical 100%.

In theory the special test wheel seems a perfect solution, until you actually break down what it realy is.

A test wheel is a metal casting that gives a load on the prop to roughly simulate what strain the motor might be put under.

Never any mention of using a different wheel for different weight of boat applications or styles of boat.

well that in itself just proves the special test wheel is not such an exact precision item. the hp variance for each wheel is also pretty wide.

this now brings us back to the using a old battered prop as a test wheel to get a fella's engine in the ball park.

he is not going to be under laboratory conditions, he just wants his motor to be near enough, just like the rest of us hope to do.

near enough is good enough when it comes to testing in a tank, because a tank test is nothing like the real thing, never will be.

I am not saying dont use the correct wheel specified, I am saying you can get away with using what is available to get it in the ball park.

its just my opinion... and its worked ok for me

-

06-29-2017, 08:12 AM #15

Well said Phil Bravo

All i am looking to do is get a ball park result

I dont now how far off i am, Nor can i justify paying £80 - £120 for a test prop that i may use a couple of times.

Its ok saying they are $35 but it then cost me $90 to get the prop to the UK.

My broken prop will be hacked so all the blades are the same length.

As for balance well she will run for maybe 5 min at a time MAX This is a test prop so i can adjust my motor. Im not driving down a loch at WOT. I have my answer to my question, Once again you guys come to the rescue

Similar Threads

-

Going to test new Dewald prop

By rapidcraft22 in forum Props, Setup, and RiggingReplies: 17Last Post: 07-07-2016, 09:15 PM -

SST 60 Test Prop

By ggoslow889 in forum PropellersReplies: 0Last Post: 06-23-2016, 03:56 PM -

prop test, need help

By hawk232 in forum Props, Setup, and RiggingReplies: 6Last Post: 02-18-2010, 10:53 AM -

OMC V4 Test Prop 100-140hp?

By Sparkroost in forum Technical DiscussionReplies: 0Last Post: 06-02-2003, 08:26 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote