User Tag List

Results 1 to 15 of 25

Thread: Tig Repair

-

08-13-2015, 11:28 AM #1

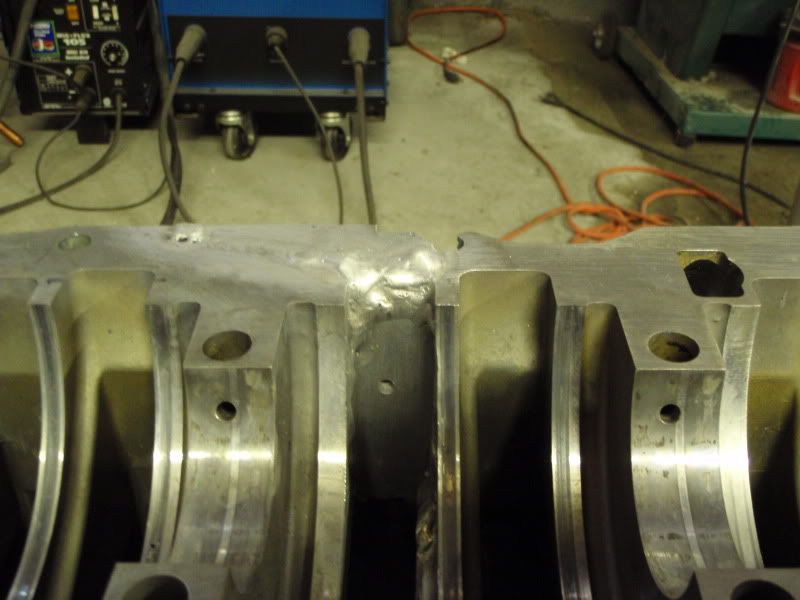

Tig Repair

I have to repair a spot on V6 Mercury block. Is 5356 filler alloy what is used when welding on a V6 block?

-

08-13-2015, 09:03 PM #2

I think the 4000 series fillers are better suited for aluminum castings.

Last edited by outasite; 08-15-2015 at 06:32 AM.

-

08-15-2015, 04:47 AM #3

4043 flows easier.

Regards,

Charlie North

If it ain't broke, modify it.

80 21' Superboat with Yamaha 225 Excel power

76 Glastron to be powered by a 6.2 L92 with surface drive

87 Glastron CVX20 Hull

-

08-15-2015, 07:02 AM #4

Tenfo got some 4043. Thanks outasite and CharlieN

-

08-15-2015, 08:00 AM #5

Post some pictures ....

-

08-15-2015, 08:05 AM #6

-

08-15-2015, 04:00 PM #7

-

COMPRECBRKR thanked for this post

COMPRECBRKR thanked for this post

-

08-15-2015, 05:56 PM #8

5000 RPM

5000 RPM

- Join Date

- Oct 2011

- Location

- Ontario

- Posts

- 370

- Thanks (Given)

- 32

- Thanks (Received)

- 46

- Likes (Given)

- 336

- Likes (Received)

- 134

- Mentioned

- 7 Post(s)

- Tagged

- 0 Thread(s)

That cup you have on your tig torch, never seen a clear one before, pretty cool.

-

08-15-2015, 06:43 PM #9

LOL, that's a very cool toy you have there......

-

08-15-2015, 10:20 PM #10

"Toys" like that allow you to keep a larger area under the argon umbrella . I pretty much just use it for stainless header tubes. That along with argon purge on the inside lets the part cool a bit before you have move off of the area. Its pretty cool .. you can run the tungsten an inch and a half out in front of the cup and it will act just like it would if were flush . You can look under , thru , behind or any situation you find yourself in . The distortion is very minimal .

Post starter , best thing to do is sand any paint , alodine or dirt at least a half inch away a from the weld site. V out the parent material about half the thickness of the part . Squirt it pretty good with acetone or lacquer thinner . Air dry and then preheat the part to around 200 degrees , Weld with 4043 , Don't overheat the part , I know it will flow like butter , but to much heat is really no good , it will let the part distort . When your done , throw a tent over it . I just use an old bent up piece of .090 aluminum , so it will come back slow ...

-

08-16-2015, 11:07 AM #11

I'll post before and after soon as I can.

-

08-18-2015, 06:44 AM #12

Junior Member

Junior Member

- Join Date

- Feb 2013

- Location

- Pittsbugh

- Posts

- 22

- Thanks (Given)

- 0

- Thanks (Received)

- 0

- Likes (Given)

- 0

- Likes (Received)

- 0

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

I used 4043 on my block. It's held together now for 3 years. (knock on wood) Oh, and I used some 6061 scrap to cover the big holes. But I tried to use any large chunks of the original block. (The flange, and the fuel pump mount boss)

A rod cap bolt walked out... and in turn... the cap blew a part, and then the crank mashed what was left of the rod though the block. It beat the piss out of the back of the fuel pump, cracked the block internal... and shattered a sleeve. But, a little TIG time took care of most of it. The home oven was employed to put the new sleeve in. (boy, the wife was pissed. LOL)

Last edited by Dr Honda; 08-18-2015 at 06:52 AM.

-

08-18-2015, 12:10 PM #13

Looks good Dr Honda.

-

08-29-2015, 06:39 PM #14

Junior Member

Junior Member

- Join Date

- Feb 2013

- Location

- Pittsbugh

- Posts

- 22

- Thanks (Given)

- 0

- Thanks (Received)

- 0

- Likes (Given)

- 0

- Likes (Received)

- 0

- Mentioned

- 0 Post(s)

- Tagged

- 0 Thread(s)

did you get a chance to start welding??

-

08-29-2015, 11:16 PM #15

Chaz you don't back gas , Dave

Similar Threads

-

STV Repair

By wplouque in forum Fiberglass and Composites DiscussionReplies: 3Last Post: 02-24-2015, 12:56 AM -

Mercury Tech: 280 ECU repair?

By PaulR in forum Technical DiscussionReplies: 6Last Post: 09-26-2009, 06:39 PM -

Repair XP

By OldSleekOlds in forum Computer and Forum SupportReplies: 8Last Post: 06-13-2008, 03:13 AM -

Repair

By tomoad in forum Technical DiscussionReplies: 3Last Post: 03-31-2006, 11:14 AM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote