User Tag List

Results 1 to 15 of 50

Thread: DougWright Flats Boat

-

07-15-2017, 12:35 PM #1

DougWright Flats Boat

.

Something wonderful is being designed at the DougWright Marine facilities. When I visited the factory on Thursday, I saw a raw block of foam. Being the inquisitive person that I am, especially when you’re at the DW factory and you have DW’s attention…I asked Doug Sr what the foam block was for? He smiled and said, “that block is our next project”. Ok, so I immediately thought that it would be for an aircraft part or a part for their new 35 foot cat. But something told me not to make any assumptions and so I just plainly asked Sr “is that for an aircraft or…” before I could even finish asking the question Sr blurted out “it’s our new DW flats boat”. I thought to myself, ok now we’re getting somewhere here. I can’t wait to tell the guys that DW is building…WHAT THE HAY! A fishing boat? So I replied rather strongly, “…wait Doug are you saying ‘flats boat’ as in shallow-water vessel to get to the Bone fish?..that kind’a flats boat? “

Sr replied “it’s really for Doug Jr, you see Jr likes to fish when he’s not in the shop”. And just at that moment, Jr comes strolling by us and asks “what brings you here Noli?” without answering Jr, I said “I want one, one of those flats boats that you’re developing”. Jr put such a big grin on his face and said, “oh that! you can buy one with your credit card…it will be very affordable”. Jr also added that you can put the whole boat in the back of one’s pickup truck and only weighs 150 lbs. The affordability and size is what motivated the build of this new DW flats boat.

And so it happened…another DW boat is born. The new boat will be available in a low powered outboard. The boat will be finished in gelcoat in a wide array of colors. The total height of the boat shall be 14” high and no more than 56” wide. The deck will have multiple variations for fish coolers, hatches for storage and live bait wells, to name a few. Jr also said "Joe P. will probably put a 90HP motor on it knowing him, but you won’t need that much power when you’re traversing the flats”

After saying my goodbyes to Sr and Jr, and after thanking them for their time I lazily walked back to my Camry and headed straight for my favorite high-end restaurant; PUBLIX! Oh you laugh, you see we don’t have PUBLIX in NJ! On my way to Publix I had more questions to ask and oh my goodness, I didn’t bother to take 1 picture…not one! As my mind was racing with more questions about this new flats boat. I quickly picked out my favorite sandwich and a salad and headed straight for the DW factory…again. This thread is definitely worthless without any pics so please enjoy the pics and as Jr sends me additional pics I will share here and if you plan to visit the DW factory, please ask to take pics of this flats boat project and share with us

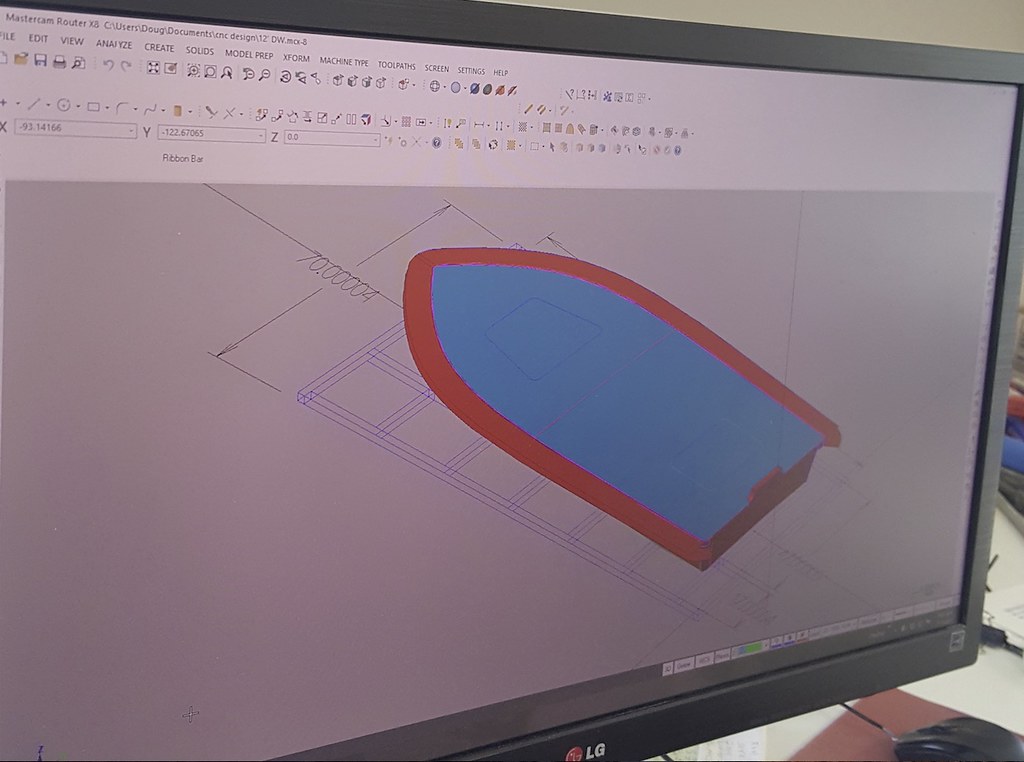

The blue area is the deck, complete with storage bins

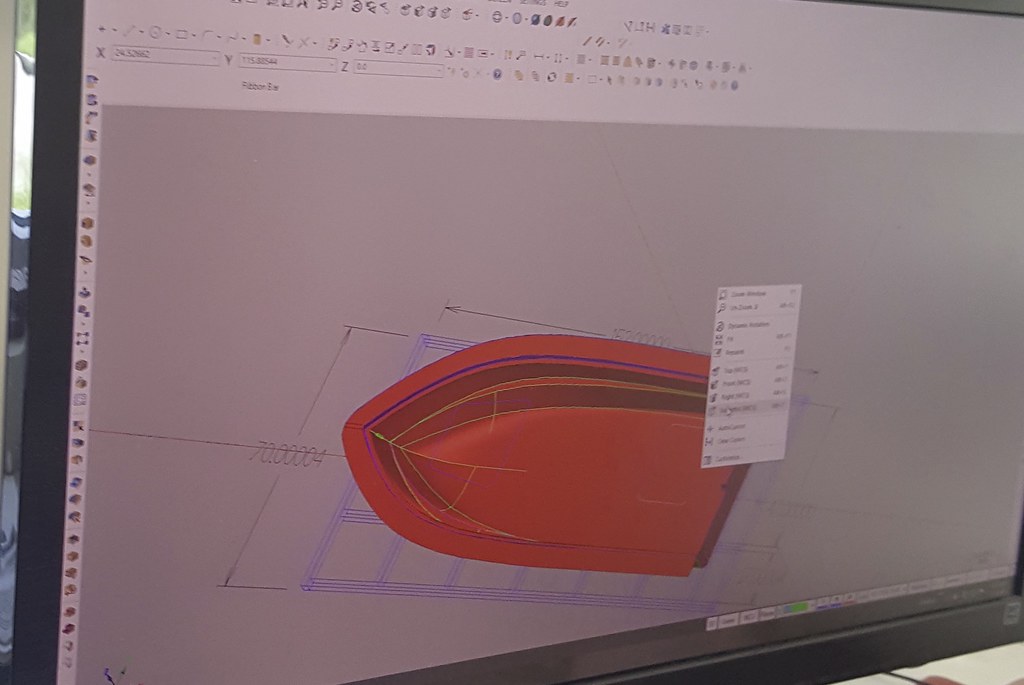

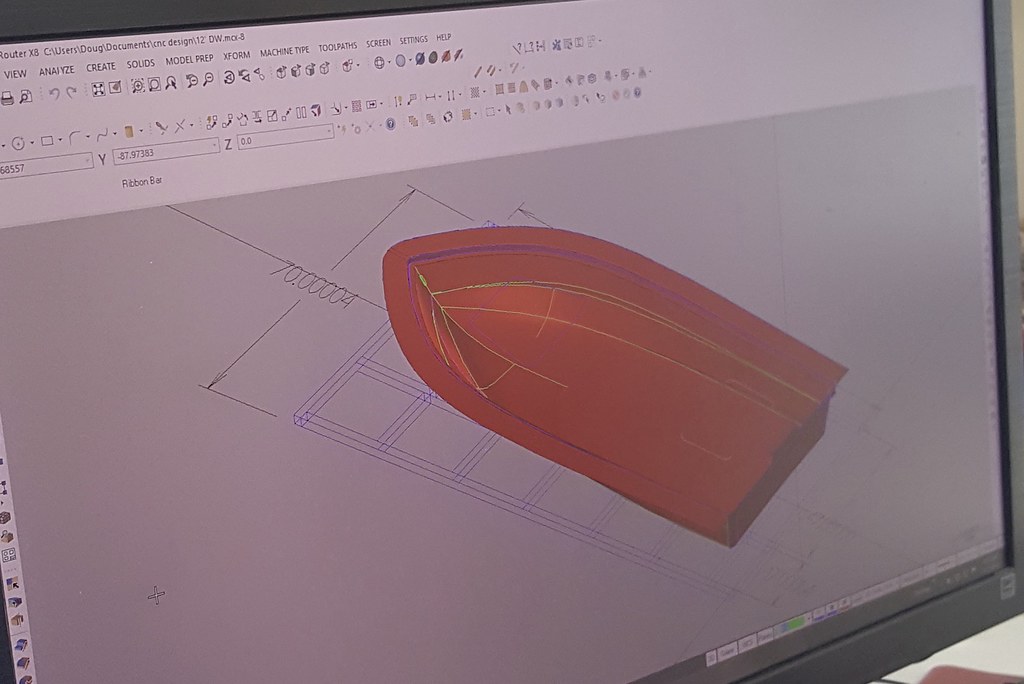

The hull-bottom

-

SLT Kota thanked for this post

SLT Kota thanked for this post

Scream And Fly liked this post

Scream And Fly liked this post

-

07-15-2017, 12:56 PM #2

.

-

07-18-2017, 10:48 AM #3

It is starting to take shape that chunk of foam now has shape saw it yesterday . I may have to add to my boat collection .Trying to get to Joe's number but cant count that high I only have 10 fingers.

24 Twister

-

noli liked this post

noli liked this post

-

07-18-2017, 04:54 PM #4

-

07-18-2017, 05:23 PM #5

Will it be foam cored?

Azure AZ259, 8.1

-

07-18-2017, 08:41 PM #6

little boxy looking, and that finish is a tad bit rough, just kidding! people are spending crazy money on flats boats these days. wish them all the best. want to launch a 16' footer myself. spotted the most amazing 16' I've ever seen. don't want to wheeze on this thread, so i'll start another one. fun out

most overnite successes usually take at least 10 years

Certified turd polisher,

-

noli liked this post

noli liked this post

-

07-20-2017, 09:13 PM #7

-

07-21-2017, 06:43 AM #8

Screaming And Flying!

Screaming And Flying!

- Join Date

- Mar 2008

- Location

- Tourist Trap, Florida

- Posts

- 14,753

- Thanks (Given)

- 381

- Thanks (Received)

- 1302

- Likes (Given)

- 5601

- Likes (Received)

- 11031

- Mentioned

- 2 Post(s)

- Tagged

- 1 Thread(s)

The only tricky thing I see is the inverted bottom. Which works well, and I have used on several boats in the past. A Sea Sled innovation. The rest is standard typical skiff shape. Boat will work well. Skiff's don't need crazy bottoms. Just stable, shallow floating platforms that move thru waves easy with a v'ed bow.

83 V-King, 96 Mariner, 200 hp ff block 2.5 w/a 28p choppa

We gotta clean this liberal mess up, VOTE TRUMP TO MAGA!

Rebuild thread:

http://www.screamandfly.com/showthre...-it&highlight=

http://www.screamandfly.com/showthre...cs.&highlight=

Videos

-

07-21-2017, 07:34 AM #9

I'd love to see a time lapse of the whole process!

I think I kind of understand how this works now...

Less dense foam is machined out rough... then denser putty applied, and that putty is then machined again for a much smoother surface?

What are the next steps?

Does this process actually make the mold, or just the plug?

Someone get that Chinese guy Tunnels in here... I'm sure he'd have a thing or two to say about this process HAHAHAHAHA. ::Face Palm::1) 1995 14' Bayliner Restoration <--Click

2) Home-Made Tunnel-Boat Project <--Click

-

07-21-2017, 07:44 AM #10

This process makes the mold, no plug needed. Once the putty is machined to a smooth surface I assume a coating is applied that creates the molds surface. What happens after that to create the finished mold ready to make hull hasn't been documented here that I can find but it would be great to see the finished product (mold) once it's ready to pop hulls.

Mark

-

07-21-2017, 07:51 AM #11

Screaming And Flying!

Screaming And Flying!

- Join Date

- Mar 2008

- Location

- Tourist Trap, Florida

- Posts

- 14,753

- Thanks (Given)

- 381

- Thanks (Received)

- 1302

- Likes (Given)

- 5601

- Likes (Received)

- 11031

- Mentioned

- 2 Post(s)

- Tagged

- 1 Thread(s)

What they pull from the foam you see here is the "master" plug. This is tested, refined and then a production mold is made from it in the conventional manner with glass and core and some sort of frame to stabilize it.

83 V-King, 96 Mariner, 200 hp ff block 2.5 w/a 28p choppa

We gotta clean this liberal mess up, VOTE TRUMP TO MAGA!

Rebuild thread:

http://www.screamandfly.com/showthre...-it&highlight=

http://www.screamandfly.com/showthre...cs.&highlight=

Videos

-

07-21-2017, 08:30 AM #12

No, that's not what they are doing, they aren't making a plug, they bypass that step.

After the green kote is applied, the putty is applied. These 2 coats are applied to prepare the female mold for milling, to cut using 5-axis CNC, into a smoother surface. The male plug build is bypassed to save time and to lower the cost of the build.Mark

-

07-21-2017, 09:02 AM #13

Screaming And Flying!

Screaming And Flying!

- Join Date

- Mar 2008

- Location

- Tourist Trap, Florida

- Posts

- 14,753

- Thanks (Given)

- 381

- Thanks (Received)

- 1302

- Likes (Given)

- 5601

- Likes (Received)

- 11031

- Mentioned

- 2 Post(s)

- Tagged

- 1 Thread(s)

Built a lot of molds? This skips a tedious step. That is all. You produce an actual prototype (hull) out of this foam mold. The foam mold is not meant to pull numerous boats out of.

Last edited by XstreamVking; 07-21-2017 at 11:46 AM.

83 V-King, 96 Mariner, 200 hp ff block 2.5 w/a 28p choppa

We gotta clean this liberal mess up, VOTE TRUMP TO MAGA!

Rebuild thread:

http://www.screamandfly.com/showthre...-it&highlight=

http://www.screamandfly.com/showthre...cs.&highlight=

Videos

-

07-21-2017, 11:12 AM #14

6000 RPM

6000 RPM

- Join Date

- May 2006

- Location

- SUNRISE FLA

- Posts

- 1,854

- Thanks (Given)

- 2

- Thanks (Received)

- 11

- Likes (Given)

- 0

- Likes (Received)

- 160

- Mentioned

- 0 Post(s)

- Tagged

- 4 Thread(s)

I was there watching myself my skate is there getiing alot of work done . Doug is something else .great guy and his brain works over time.hes also doing a 12 ft skiff.it was being cut when i was there .4 a guy that had a stroke he dont miss much.red rocket out

-

07-21-2017, 06:50 PM #15

Similar Threads

-

DougWright 32 RT

By noli in forum Photos and VideosReplies: 52Last Post: 04-21-2020, 11:00 PM -

DougWright building 32 Race Boat

By noli in forum General Boating DiscussionReplies: 1Last Post: 12-11-2016, 12:11 PM -

Bass Boat to Flats Boat Conversion

By skatermike24 in forum General Boating DiscussionReplies: 10Last Post: 12-13-2014, 09:23 PM -

89 Laser bass boat conversion to flats boat

By 89LaserBass in forum Fiberglass and Composites DiscussionReplies: 7Last Post: 10-29-2014, 07:14 PM -

Bass Boat Flats Boat Prop

By Dingie 2 in forum Technical DiscussionReplies: 3Last Post: 01-13-2012, 08:29 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote